Coastal Enterprises, manufacturers of Precision Board HDU, is proud to host guest blogs written by some of the industry’s biggest movers and shakers, posted to the Precision Board Blog. This guest blog is written by Jody Wyse, Western Regional Sales Manager for Hawkeye Industries, manufacturers of Duratec polyester and vinylester coatings, headquartered in Bloomington, California.

In our February Tooling Tidbit e-blast we talked about the benefits of using Precision Board urethane tooling board for soft tooling applications. In this month’s guest blog, Jody discusses the benefits of using Precision Board Urethane Tooling Board over other soft tooling substrates like MDF and EPS.

In Jody’s own words…

My previous blog was about the various Duratec coatings that could be used on Coastal Enterprises’ Precision Board Tooling Board and was a broad discussion of products in general. In this latest blog entry, I will cover the beginning steps for choosing the correct substrate for a tooling project.

Not every tool, plug or shape being made needs a perfect surface. In fact, I’ve used everything from a sheet of 6mil plastic over a dirt shape dug in the ground all the way up to high end metal tools. Both surfaces were the correct ones for the jobs being done.

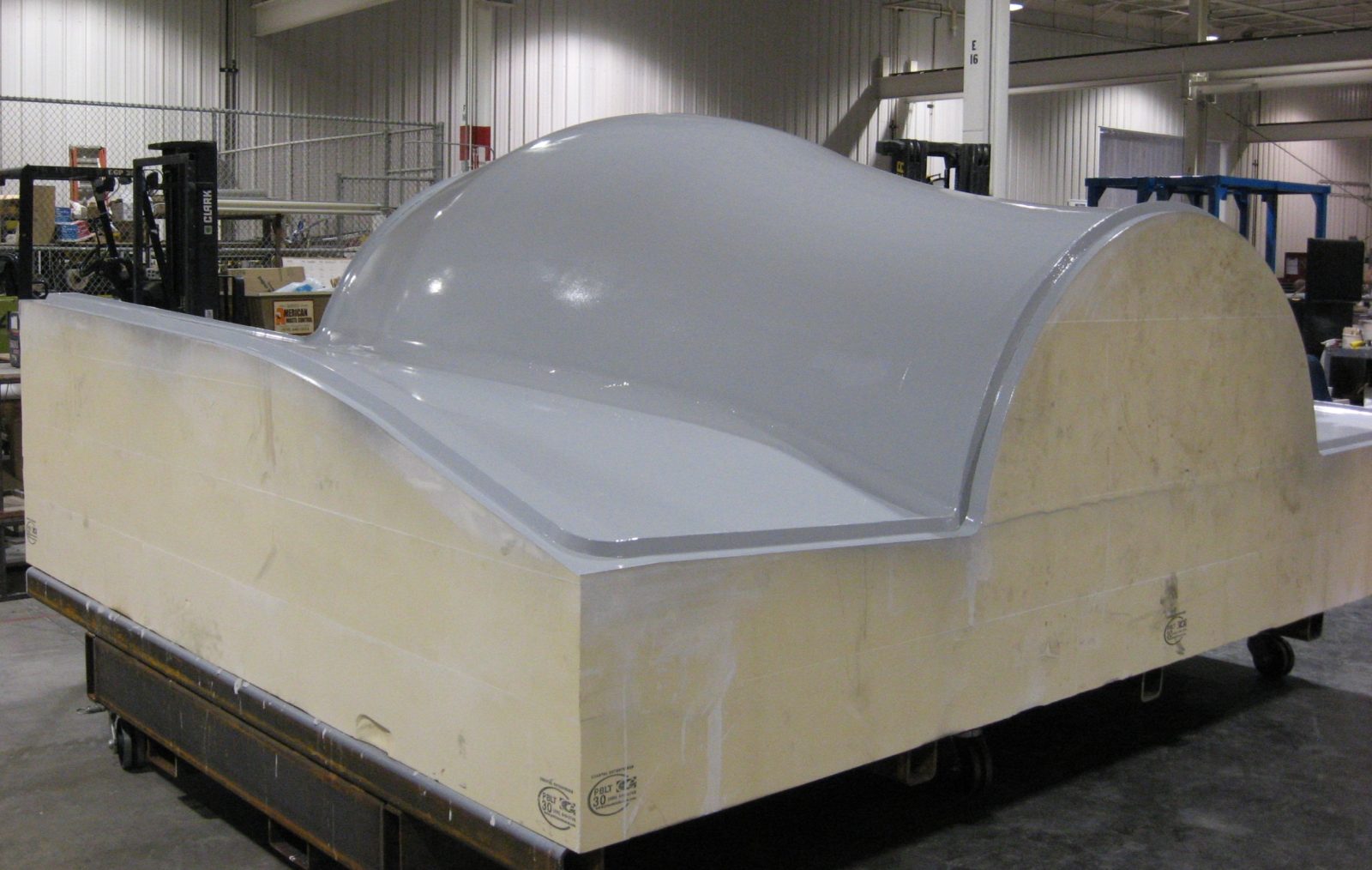

Tooling board comes into play when you need a reliable and dimensionally stable substrate and you don’t want any unpleasant surprises at a time when it is too late in the process to make simple and cost effective changes. Sometimes the problems don’t show up until the final stages of the project, like when the first part, or the permanent final tool is being pulled from the mold or plug you spent the last month (maybe much longer) and possibly hundreds of man hours building.

People frequently ask about using MDF or EPS foam as a substrate for a plug or tool. These materials work, but it’s not what they were designed for. They just happen to work in non critical parts, and they work adequately at best. The most common reason for using these products is the low upfront cost. Another reason is a low number of parts needed (5 or so identical parts off the shape, and the dimensions are reasonably critical, and so is the finished surface of the final part).

Let’s take a look at each of these materials.

MDF (Medium Density Fiberboard)

MDF is cheap, but the quality and consistency is very unreliable. What you buy today may be very different than what you buy tomorrow. Even sheets in the same stack can have very different properties. One big problem with MDF is that it’s always changing shape. MDF is very sensitive to temperature and humidity. So whatever shape you make today will have changed by tomorrow. This gets worse over time, and the changes can be amplified after the first part is pulled from the shape.

After the first part is pulled from an MDF plug or tool it will normally have changed dimensionally, plus the surface profile typically deteriorates. All the work put into creating a shape with the correct dimensions and surface profile may need to be done again, resulting in delays and more man hours, which can increase the costs rapidly.

EPS (Expanded Polystyrene)

EPS foam is cheap, but it can be difficult to shape depending on the density. Low density EPS tends to crumble or come off in small chunks when using hand tools. It also requires different coatings that are compatible with it to create a surface. One of the bigger disadvantages is its very low strength. Rarely can you get more than one part off of an EPS shape, so it normally is used for only that one part.

Conclusion

This doesn’t mean MDF and EPS should never be used, they just have some very limiting physical properties that may be very difficult and expensive to work around.

Precision Board Urethane Tooling Board can be chosen to meet the exact set of physical properties needed for the job, no more, no less. The experts at Coastal Enterprises can help guide you to the correct product for the current job that will save you both time and money.

Having a substrate that is the same today, tomorrow and next week, is required when the surface profile and shape are important. And if more parts are needed off the same shape, a higher density of Precision Board tooling board can be used to increase its durability.

I make samples to show customers using MDF, EPS and Precision Board so they can see first hand the differences in each substrate and what to expect in the finished shape. I also show them what each surface looks like after the first part is made off of it. They are frequently very surprised at how different the surface quality is after only one use.

In some cases the parts made off of low quality substrates need to be extensively reworked before they can be sold or used for their intended purpose. This usually means the original shape also needs similar extensive rework before another part can be made from it, and that’s only if it survived the de-molding process, which they frequently don’t.

My next guest blog will go into the details of cost effectively choosing the correct Duratec coating(s) to achieve the desired surface properties on different densities of Precision Board tooling board.

Hawkeye Industries is proud to be the master distributor of the Duratec line of putties, primers, sealers, and topcoats. Duratec Polyester and Vinyl Ester products are famous for their ability to cure completely when applied to plug/pattern surfaces. That thin-film, air-cure capability makes Duratec ideal for the composites industry. Check out their website or give them a call at (909) 546-1160 0r (800) 977-0060 if you are interested in more information on how Duratec products work with Precision Board tooling board.

Coastal Enterprises manufactures Precision Board, a versatile, cost-effective and eco-friendly urethane material used extensively in the tooling industry. It is a closed-cell, rigid, dimensionally-stable substrate that is ideal for use in a number of different tooling applications. Request free samples, get a quote or sign up for weekly e-blasts packed with helpful information.