What are the benefits of having the correct cutting bit, and proper speed and feed settings on your CNC router?

- Better Chip Load

- Less Time Routing

- More Chips, Less Dust

- Increase The Life Of The Cutting Bit

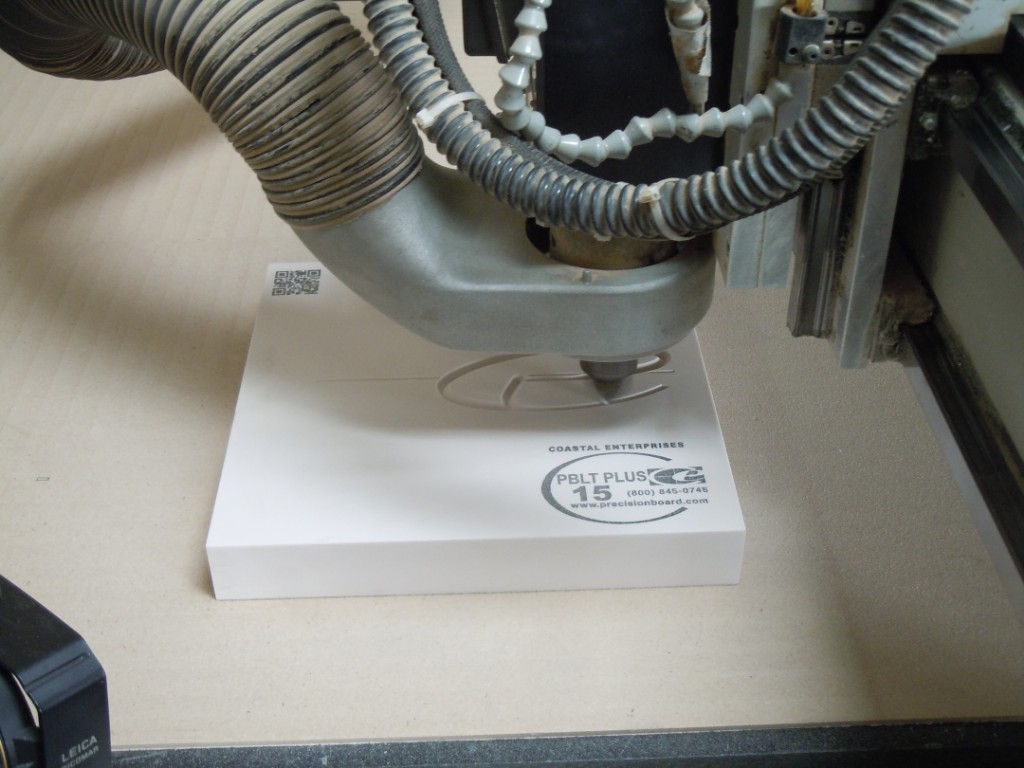

We recently had some Precision Board Plus tested by our friends at LMT Onsrud, router bit manufacturers and expert CNC machinists, to find out the best speed and feed rates for specific densities of Precision Board Plus. The information was collected to add to the excellent router bit selector guide LMT Onsrud has, which recommends router bits as well as proper speed and feed based on selected density of Precision Board Plus. You can check this guide here.

We were additionally offered the opportunity to speak with Gary Burgus, one of LMT Onsrud’s expert Engineering Technicians (and the man who tested all the Precision Board) and walked away with some valuable information from someone who has tested hundreds, if not thousands of different materials with many CNC router bits.

All of the cutter bits Gary used were carbide tipped, but it is not necessary to use carbide with Precision Board Plus. Any HSS (high speed steel) cutting bits can also be used.

General Routing Tips for Precision Board Plus:

- Cut in a conventional direction, Precision Board Plus cuts similar to a foam type material

- Heavier cuts are generally better, specifically a full diameter or half diameter pass because the tool needs material to grab and cut away. Many customers who are familiar with cutting hard plastic or metal are accustomed to taking light radial cuts. Because Precision Board Plus is more similar to foam, the tools need more material to grab – be sure to leave a 50% radius.

- Routing to depth is preferable over plunging to depth

- Always maintain a constant chip flow

- If you are cutting a large rectangle, or low detail shape, a 2 or 3 flute tool is your best choice. This will maintain a constant speed and feed rate.

- If the shape you will be cutting is highly detailed, stick to a single flute tool, run it a little slower and keep a constant feed rate.

Gary also provided us with a great example:

Say you are going to cut a highly detailed sun, 20″ in diameter, and and set your CNC router to 10,000 RPM at 200″ a minute. Because the direction will be changing so many times, a single flute tool is preferable. Even though the settings call for 200″ a minute, realistically the most you will be seeing is 60″ – 100″ a minute. Using a single flute tool will allow for the best chip load and cut.

If you are going to be cutting letters, if they are 2″ or so, a single flute tool is preferable. If the letters are 10″ – 12″ or larger, a 2 flute tool is your best bet for the ideal chip load.

Be sure to check out this excellent guide that LMT Onsrud has for selecting the proper bit (select high density urethane and proper density) at: http://www.plasticrouting.com/BitSearch.asp?Page=Material.

This video shows PBLT-30 being routed on a Zund G3 CNC router with the proper speed and feed, talk about some fast routing!

If you have any questions, we offer free technical support and can be reached at: (800) 845-0745.