Blogs

Renovations Part 1.

A few months ago, I walked in the shop and stopped in the entryway. I looked around and thought, this is nice, but it’s not really Synergy. After some careful brainstorming, the hammers came out, the paint brushes began to fly, and the Multicam CNC Router began cutting parts. The first step was to texture all of the walls with Coastal Enterprises TSF 45 texture coating. We used 3 gallons putting a nice heavy texture on the walls.

New Challenger: Phase Two: Turning 2D to 3D, It’s harder then it sounds

I have a concept, I figured out my scale, now to start actually building… ugh… Where to begin? Jim and I sat down with my concept sketch and started figuring out materials we should use. This can somewhat be overwhelming, but we approached it by dividing the piece in half. We started with the base, The bottom pretty much needs to be the strongest and most durable

New Challenger: Phase One: Use all the math you learned in school, that you never thought you’d actually ever use.

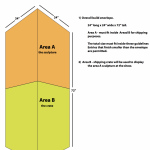

Phase One: Use all the math you learned in school, that you never thought you’d actually ever use. I have a concept! Now what do I do? Well… I guess I can put the engineering degree to use and start drawing my piece to scale. I started with the basic dimensions a 24in x 24in base, as stated in the contest rules with a total height of 72 inches. Easy enough, right

New Challenger

A few months ago the invites for The Sign Invitational went out, I thought nothing more about it really besides the theme and some ideas came in mind for the shops entry. As some of you may know, Jim and the shop helped organize a contest last year, where a bunch of sign makers challenged each other to create a dimensional display piece. Synergy pla ced 3rd and that was the first month I started at the shop and my first big project.

How it’s Made: Fabricating a Composite Truck Cab

Since 1999, Daycab Company, in Rockwood, TN, has been using composites to retrofit class 8 commercial trucks with sleeper cabs to day cabs. Why would anyone be interested in having the sleeper cab removed, and a composite day cab installed you ask? Once a commercial...

Speeds and Feeds for Optimal Precision Board HDU Machining

HDU Machining with Precision Board Plus One of the more frequent inquiries we receive at Coastal Enterprises involves questions about machining Precision Board Plus HDU. For those that are experienced in working with the product, we typically hear things like, “this...

What’s behind door #1?

A while back, I started brainstorming what our entry way should look like. It was pretty drab and boring, so it was in need of a major upgrade. The first thing that popped into my head was some neat looking gear themed window sills.

Fantastically Rich, Beautifully Strange: Workspace Renovations with Synergy

Workspace Renovations with Synergy Sign and Graphics Every once in a while, a skilled sign maker finds his workspace in need of some sprucing up. For top-tier craftsmen who make their living churning out beautiful, skillfully executed creations, it's only natural that...

Precision Board Donations: Supporting the Future of Composites

Sponsoring Schools with Precision Board Donations Here at Coastal Enterprises, we place a lot of importance on the future of composite materials. Space travel, aeronautics, construction, and many other industries depend on the advancement of different composites...