On Friday it was time to put our first real project on the four axis MultiCam and give it a whirl. IT would be the hot air balloon. We would cut it from a large block of 30 lb Precision Board measuring 14″ x 14″ x 20 ” long. We had previously drilled a hole in the center of each end and driven in a pipe. This would be our clamping point for the lathe. The routing operation would be in three phases. The first was the true lathe mode. Here we would assign a steady feed rate for the y axis. The z feed would be done in three passes as a straight line across the piece each time. The second operation was the roughing done in four passes. This was done with a half inch ball nose bit with a 50% overlap. The final operation was the cleanup pass done with a 3/8″ ball nose bit and a 95% overlap. A higher than typical overlap was necessary because the piece had a big diameter and the degree of rotation meant a greater distance corresponding to the distance from the centerline. Here’s a short video showing the various passes…

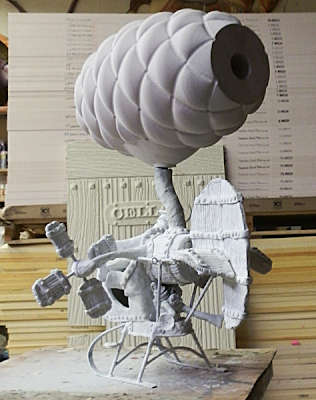

As soon as the piece was done I removed the steel pipes, drilled a hole and mounted it to the driver’s cab. It was looking pretty close to my illustration already.

in the next installment we’ll be designing and routing the nose and tail cones for the balloon to finish off the sculpting process. Then it is off to the paint department. Stay tuned…

-dan

Published with permission from precisionboard.blogspot.com. Source.