Following up on my previous post on my method of making high quality, re-usable tooling with CNC machined foam and Stretchelon bagging film, here’s how things tend to go on the demold side. First, turn off the pumps, and then remove all the secondary fabrics/films that are bagging the part:

I’ve left the peel ply on here, because the parts are still pretty darn soft, but everything else has gone into the trash. Now, simply get some air underneath the layer of Stretchelon covering the mold, and then pull the parts up, along with the film:

Now, just simply peel the Stretchelon off the parts – if you’ve used mold release, it should come off very easily more or less in one piece:

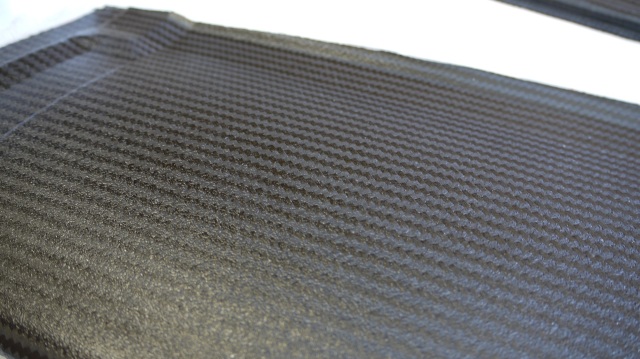

Presto! And the molds are totally unharmed – same as they were when we started. Here’s a closeup of the surface texture of the finished part:

Yes, a bit of texture, but like I said before, a few swipes with some 80 grit to prepare for primer and the texture just vanishes. Or, if you really want a smoother texture, just get more dense tooling foam.