Great things are happening at Spec Formliners, manufacturers of formliners, in Santa Ana CA! It might not be widely known that Precision Board Plus is used in the architectural concrete forming industry. Their end products are molds that attach to the inside of concrete forming systems. When concrete is cast against the form liner, the impression is left in the resulting concrete wall.[/one_third] [divider_padding]

The patterns available are abundant and can range from simple flutes or wood grains to elaborate custom murals such as aquatic life scenes or rolling wave patterns. “Our manufacturing process is simpler, cleaner, and faster because we are able to use our two CNC tables to produce our master molds with Precision Board Plus. Designs are pre-approved by our customer and then precisely replicated on the CNC in Precision Board, allowing for quality control that was not achievable in the past.” says Drew Deering, Vice President of Engineering.

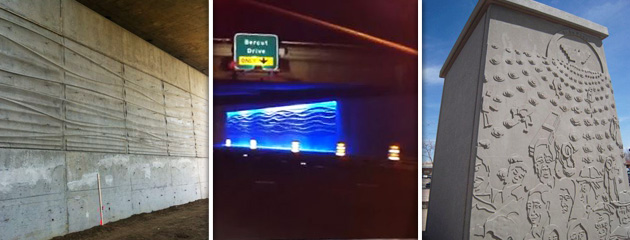

1. Precision Board Plus being machined 2. Precision Board Plus master mold used to cast formliner (primed in gray) 3. Finished polyurethane formliner ready for customer use.

“We use Precision Board in favor of any other machineable material because of its ease of use. Precision Board allows for the longest bit life, the fastest machining speeds, and a more uniform finished product than other machining board. We commonly glue multiple sheets together or order certain thickness of Precision Board in order to meet the specific requirements of a project – something that is not easily achieved in any other material. Additionally, the composition of Precision Board creates a larger, denser particle when machined that settles very quickly, so our employees are not surrounded by a cloud of dust the way they are when we machine MDF,” says Michael Billing, Design Engineer, “We are very concerned with shop environment as well as the satisfaction of our customers.”

For more information on Spec Formliners – give them a call (888-429-9550) or view their web site at www.specformliners.com.