Practice makes perfect as the University of Nevada Concrete Canoe team “Dambitious” paddles to an overall win in this year’s regional concrete canoe challenge known as the Mid-Pacific Conference.

The University of Nevada team finished first place in all 5 races in the competition that took place at Vasona Lake in Los Gatos, CA on April 19th. Individual events included men’s and women’s sprint (200 meters) and endurance races (600 meters), with the final race being a 400 meter co-ed race.

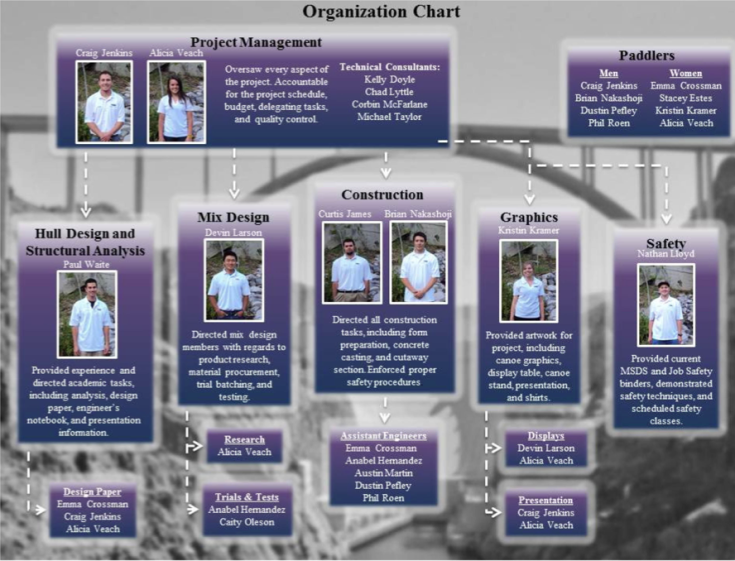

We had the opportunity to speak with Alicia Veach, Project Manager for the University of Nevada canoe team this year, about just how they were able to finish with such high standings. Alicia attributed the win to their practice regimen and a very well designed canoe hull. The mold for the canoe was made from Precision Board Plus donated by Coastal Enterprises.

The competition-winning hull was created by analyzing different hull designs using a unique Excel program called Aqua-holic, which was developed by the 2008 U of N team. Theoretical results based on submerged shape, length and beam evaluated straight line speed. An empirical equation in the spreadsheet estimates the time required to complete a 180-degree turn. Ducimus, the 2012 team, was selected as a preliminary hull design because it had the greatest top speed and the second fastest turning time compared to four previous Nevada canoes. (Courtesy University of Nevada Mid-Pac Research Paper).

After selecting the Ducimus hull, changes were made to improve straight line speed and manueverability, thus creating the 2013 “Dambitious” canoe design. After the design was finalized, Precision Board Plus PBLT-4 HDU was CNC machined to create a mold (To see the mold being machined click here). Concrete was then poured into the mold and allowed to cure for 28 days before being released from the mold.

In the past, cutting the canoe free from the mold has not been an easy process. This year however, the Nevada team constructed an innovative air release system. Team members drilled two holes through the form at each transverse rib location. Each of the eight air ducts were then connected using PVC pipes. The end result was the introduction of air into the system provided enough pressure to release the canoe from the form.

The next step was a lengthy period of sanding, starting with 80 grit and working up to 1000 grit, until the desired shape was attained. Numerous items such as wooden blocks and shop lights were used to locate high and low spots and ensure even sanding.

After the sanding was complete, the final step was making it an aesthetically-pleasing product. Non-toxic, eco-friendly concrete stains were used for the majority of the finish while an air brush and stencils were utilized to apply the graphics.

Winning first place overall doesn’t just depend on winning all the races either (which seems like a pretty big feat anyways!), there are 4 categories that make up placement score:

- Races – 1st Place

- Design Paper – 1st Place

- Final Product Score (canoe finish, concrete samples, display) – 1st Place

- Presentation – 3rd Place

Coastal Enterprises would like to congratulate the entire Concrete Canoe team at the University of Nevada on their win! They now move on to the National Competition which will be held at the University of Illinois at Urbana-Champaign, Urbana, IL from June 20-22.

To see why they race concrete canoes (and more of how the U of N built their canoe), visit our previous blog: Racing Concrete Canoes Part 1.