The University of Michigan Formula SAE team recently competed in the Formula Hybrid International Competition. Closely related to the Formula SAE competitions we have written about in the past, Formula Hybrid is widely regarded as the most challenging of the SAE CDS competitions. As a matter of fact, an unofficial Formula Hybrid slogan is: “Formula Hybrid – Everything else is just too easy!”

The competition includes acceleration, autocross and endurance events. Student teams design and construct a Formula Hybrid car powered by electricity and combustion, and are responsible for building all aspects of the car from high power electronics to mechanical systems.

One of the most impressive features onboard the University of Michigan car is a system known as the dSPACE MicroAutoBox II, which is an electronic brain designed to regulate the rpm’s of the two electric motors onboard. The electric motors power individual front wheels, which coupled with a 250cc combustion engine, enable the car to achieve superior acceleration. This feature earned U of M students the Chrysler Innovation Award, which came with a prize of $1,000.

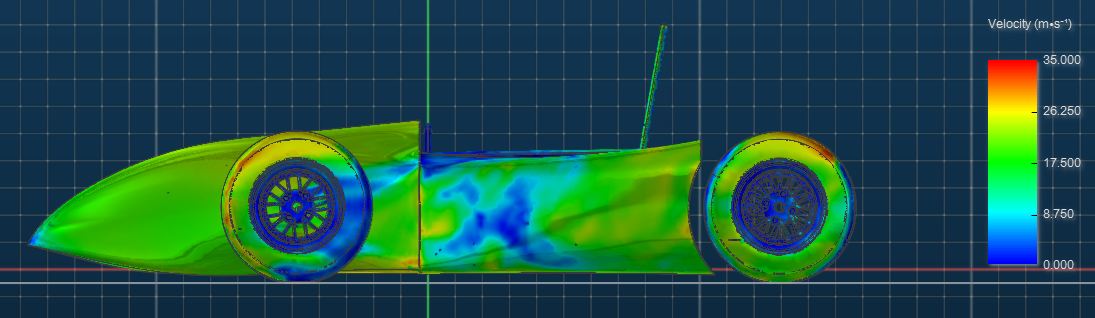

Formula Hybrid Co-Captain Kara Stoltze was kind of enough to put me in touch with A.J Jayasinghe, Aerodynamics Division co-lead, about just how the students designed this car. Body design was created using Solidworks, and the aerodynamics were analyzed using X-Flow, which is a software program by Next Limit Technologies.

After the car was designed and the students were sure they could make a mold based off the design, they used a CNC machine to create the molds using a combination of Precision Board Plus PBLT-10, PBLT-15, PBLT-20 and PBLT-30, donated by Coastal Enterprises. The molds were then coated with Duratec and allowed to cure before using them as plugs for the aerodynamic body and other interior components. According to Miles Justice, also Aerodynamics Division co-lead, the Precision Board Plus worked great because of how fast it machined and how easy it was to laminate together.

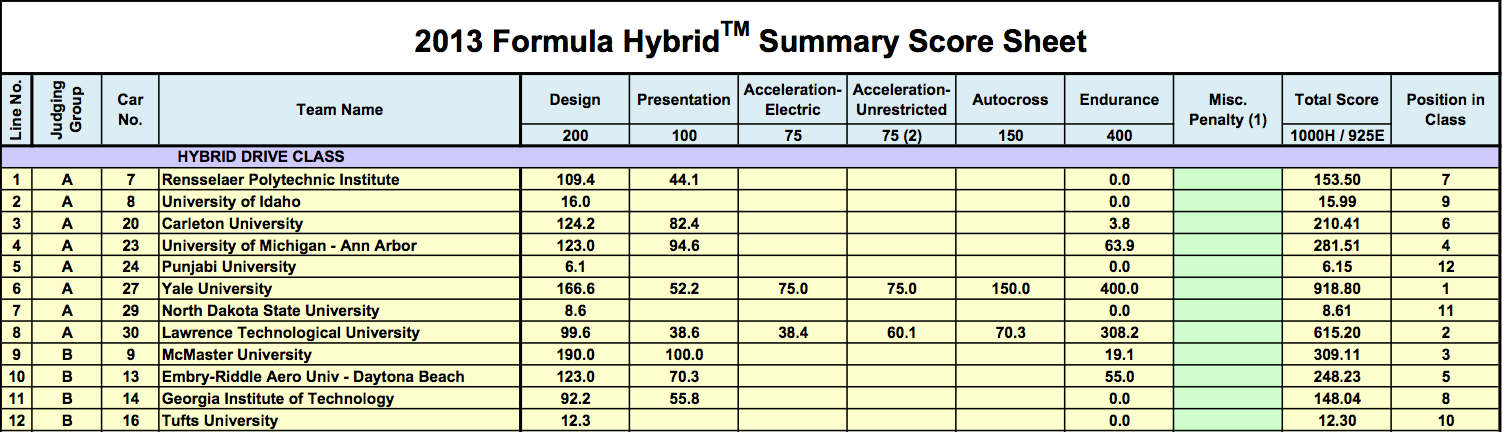

Unfortunately on race day, the discovery of a fuel tank leak and a short in the cooling system during a pre-race technical inspection forced emergency repairs on the students before they could enter the competition. This caused them to miss the first two dynamic events with significant delays ultimately affecting their overall score. Continuing on and fighting hard, they still managed to take 4th place overall out of 12 competing schools.

According to Kara, “The biggest challenge with Formula Hybrid is, by far, integrating the two powertrains to have a succesful hybrid. Getting both powertrains to work is one thing; getting them to work together is a whole different ballgame.” Coastal Enterprises would like to congratulate the entire University of Michigan Hybrid SAE team and wish them luck on next year’s car!