Having a vivid imagination in the design world is an asset, but being able to realistically apply it in the real world is a learned skill.

Within the Department of Architectural Technology at the New York City College of Technology (CUNY) , the Introduction to Computation and Fabrication course aims to teach students introductory CNC techniques, with added focus on Design for Manufacturability.

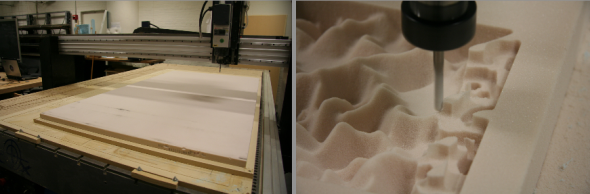

Using parametric software such as Grasshopper in combination with RhinoCAM, students are taught to create their own tool paths. These tool paths are then “proofed” on a CNC machine using a variety of materials, such as Precision Board, to analyze the design for imperfections or errors.

If the student has designed a complex tool path with many tight, narrow valleys, they may realize as a consequence that the machining time is far too long – with the result being a design that no customer could afford.

If the tool path proves successful, the design is then produced on materials including Precision Board Plus HDU. The goal of this is to teach students that when they design something, they should also have a pretty good idea of the output technology required to bring their design to life.

Additional information on the Introduction to Computation and Fabrication course, taught by prof. Anne Leonhardt and Zach Downey, can be seen at: http://openlab.citytech.cuny.edu/compfab/.

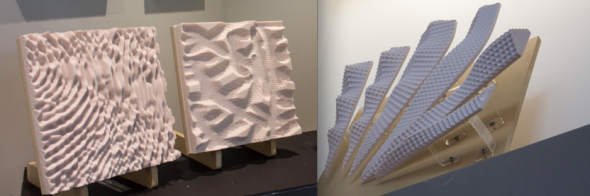

Brian Ringley, Technology Coordinator for the National Science Foundation ATE Fuse Lab grant program which initiated the course, sent us pictures of several projects featuring Precision Board donated by Coastal Enterprises from their exhibitions.

These pictures show student-created projects made using Precision Board Plus PBLT-4, PBLT-6 and PBLT-8 for the Intersections 2013 exhibition:

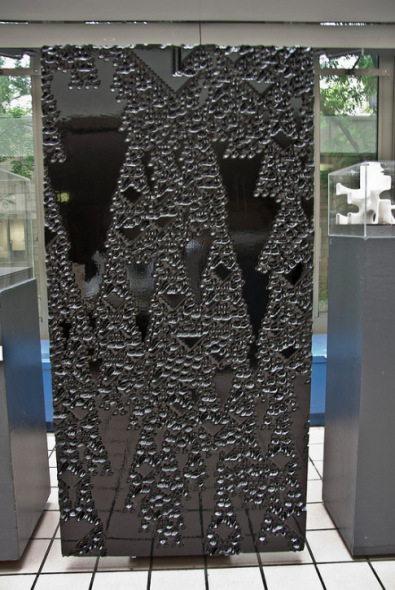

This project was created by esteemed artist and designer Francis Bitonti as part of a student-artist collaboration exhibit called “Intersections” held in 2012. The project is titled the “Schistose Mirror” and shows Precision Board Plus PBLT-10 mounted onto Trupan MDF being cut on a CNC router. After it was CNC cut it was professionally painted by an auto body shop. See more work from Francis Bitonti at: http://francisbitonti.com