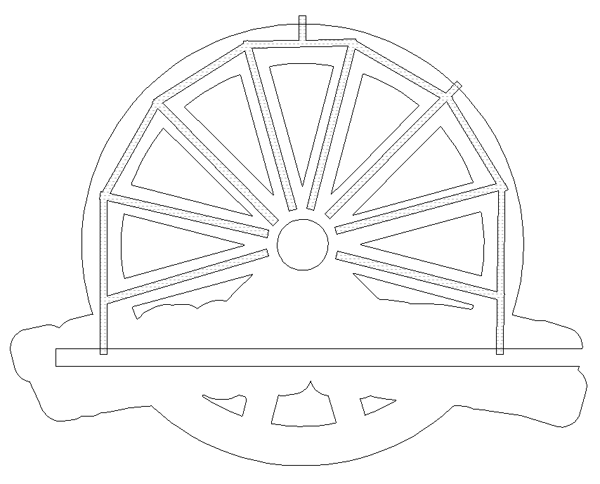

The wagon wheel sign pieces have gathered dust for almost a month as we were so busy with other things. Today the shop was quiet and I finally got the chance to do some assembling. First I had to create a file and cut the center layer to accommodate the steel frame. This frame would be welded up segments of 5/8″ steel rod and a piece of horizontal 1.5″ square tubing. The slots for the 5/8″ tubing would be cut into the material. The square tubing slot was to be cut as part of the offset outline milling.

Here’s the shot of the tool paths ready to be sent to the MultiCam.

Once I had cut the piece from 30 lb Precision Board it was ready to assemble with the rest. I cut and laid the steel into the slots and then tacked it in place using the actual wheel as a jig. The pieces were then removed and welded solid.

I then used PB Bond 240 glue, a one part adhesive made by Coastal Enterprises to fasten the components. I also used plenty of screws to clamp things together and keep them in line. These screws will stay in place.

The project had six layers in all which makes for a pretty beefy sign!

-dan