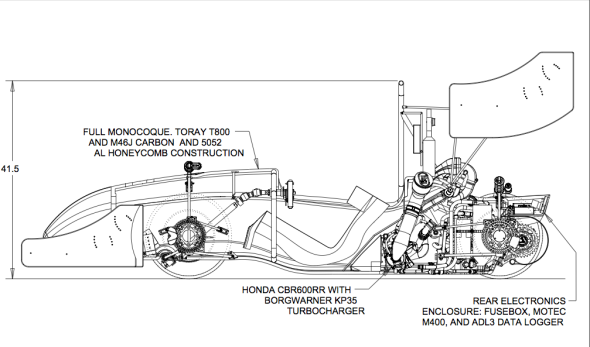

Anytime a project involves adding a motorcycle race engine to a four-wheel chassis, its bound to be pretty awesome. Cornell’s 2014 FSAE car, ARG14, weighs in at only 420 lbs. and boasts a turbocharged 2007 Honda CBR-600RR engine and complete carbon fiber monocoque frame. ARG14 got a chance to bare its teeth this past month when hundreds of teams from all over the world got together with their formula-style race cars for Formula SAE Michigan, held at the Michigan International Speedway, to find out which school brought the fastest car and who would walk away with bragging rights till next year. It’s a tough competition, with some teams utilizing professional drivers and Formula 1 wind tunnels during the car’s construction – these teams are serious about winning. Cornell 2014 FSAE Team Leader Jesse Green describes the changes they made prior to the 2014 race: “This year we made several major changes to help us achieve our goal of winning the competition. The first was the addition of an aerodynamic system, to increase the drivability of the car and and maintain competitiveness, as many other FSAE teams have also been adopting aerodynamics.”  In order to implement this major change, the first thing students did was perform a vehicle stability analysis with a two wheel model. With this, students were able to determine the minimum aerodynamic forces needed to stabilize the car, and a baseline for the desired aerodynamic balance. Additional testing helped students establish target lift and drag values, enabling them to accurately calculate desired aerodynamic performance and come up with a model to provide the most beneficial amount of downforce. According to Jesse Green, “We used the Precision Board Plus donated by Coastal Enterprises to make master molds for the carbon fiber parts that make up the aero kit. We had experience with Precision Board from when we made the molds for our carbon fiber monocoque frame in 2011, and it worked perfectly to produce our aero kit with minimal time or effort.” By generating 300lb. of downforce at 60mph, the team could attend Formula SAE Michigan confident that their car would perform well at the race.

In order to implement this major change, the first thing students did was perform a vehicle stability analysis with a two wheel model. With this, students were able to determine the minimum aerodynamic forces needed to stabilize the car, and a baseline for the desired aerodynamic balance. Additional testing helped students establish target lift and drag values, enabling them to accurately calculate desired aerodynamic performance and come up with a model to provide the most beneficial amount of downforce. According to Jesse Green, “We used the Precision Board Plus donated by Coastal Enterprises to make master molds for the carbon fiber parts that make up the aero kit. We had experience with Precision Board from when we made the molds for our carbon fiber monocoque frame in 2011, and it worked perfectly to produce our aero kit with minimal time or effort.” By generating 300lb. of downforce at 60mph, the team could attend Formula SAE Michigan confident that their car would perform well at the race.

Precision Board Plus PBHT-40 for the carbon fiber monocoque frame being CNC machined by Sierra Technical Services.

Precision Board Plus PBHT-40 for the carbon fiber monocoque frame being CNC machined by Sierra Technical Services.

Cornell’s ARG14 ended up placing 44th out of 107 different teams, and are walking away with valuable insight from the new techniques implemented this year that they plan to master for next. According to next year’s Team Leader, Nina Buchakjian, “Cornell Racing has a strong heritage of building extremely powerful racing vehicles with incredible acceleration times. We definitely plan on continuing this for our next prototype, the ARG15. One major change will be in our chassis design, which is still being finalized. The redesign will focus on making the engine more accessible and serviceable. And of course, we aim to win!” See more about the Cornell FSAE team at cornellfsae.com.