I witnessed a CNC router for the first time at the International Sign Show back in 2006. I was amazed to see the machine going back and forth cutting so very fast. The machines I saw at that show were all doing cuts and not 3D. Few people were doing 3D back then. Over the course of the three day show I looked at many routers and talked with the software folks at length about what these machines were capable of. In a word – ANYTHING. Anything I could think of the machines could do.

Keep in mind that I have never owned a plotter of printer, had never even built vector files to this point. The language and terms I heard at that show were all foreign. I had so much to learn. By the end of the show I only knew one thing. I had to have one of these machines in our shop.

When I got back home the work began. A cnc router wasn’t to be a small investment. After the purchase of my building it was the next biggest number. As I got into my research I quickly discovered that the router alone was only part of the cost. I also needed a good sized compressor, an air dryer, a dust removal system, and software. Then there was the electrical needs and the time to learn how to use it as well as build a market to sell the work I would produce on the machine.

I first had to educate myself about the specifications and options available on the routers. As I stated before the terms I heard to this point were confusing.

Stepper motors were common back then, servos only came on the more expensive machines. Through talking to many owners of machines across the continent I learned that steppers were slower, and if pushed too hard would lose their way. Servos were closed loop and were better. That was a no brainer in my book for I tend to push my equipment hard. Steppers have improved since then but based on my experience I would still only consider servos if I had to do it again.

Gantry height was the next thing to consider. I learned that the higher the gantry the more shake was possible. I also learned that by beefing up the structure and bearings this movement can be eliminated. Heavy duty wins the day here. While the height of the gantry was important the limiting factor was more about the length of the tool. The longer the tool, the more deflection was possible. This translates to less accuracy, chatter, and tool breakage. There is also what I term the cone of death. This is a triangle defined by the tool length and collet size. If your tool is only two inches long you can’t cut deeper than that (vertically) without bumping the collet. In the end I settled on six inches of gantry clearance and it proved to be right. I got a very stable machine that could be run at high speeds. I’ve never cut material thicker than four inches.

Table size was the next question. I had to think about what I would be cutting. All of my substrates come in 4′ x 8′. This included high density urethane, MDF and plywood. Shop space was also factored in. I never planned for a router when I built it and space was at a premium. I decided a 50″ x 100″ router would work just fine. You also have to plan how you are getting the router into your building. I know people who have had to take out walls to locate their machine. We had to hire a heavy duty forklift for the task.

Electrical needs will have to be addressed and this adds up in a hurry. We only had single phase power in our shop with no option to upgrade to triple phase. This meant we had to have our router built with an inverter. It takes 60 amps of power to run the machine. Then there’s the vacuum pump and the dust removal system. New heavy duty wiring had to be run for all of the components.

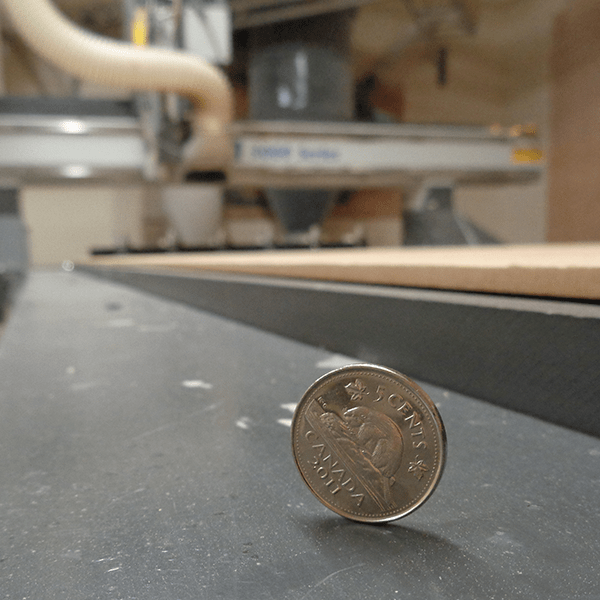

There has been a great debate for many years about the construction of routers. Is heavier steel construction better than lightweight aluminum? In one camp weight is your friend. Heavy duty castings and I-beams absorb the forces and vibrations. Strong servo motors allow for quick changes in direction. In the other camp everything is lightweight aluminum. The thought is that everything can change direction quicker if it takes less force due to less mass. When a machine is cutting a true 3D file it changes direction quickly and often. This produces a lot of force and vibration which affects cutting quality. I like to do what I call the nickel test. With the machine going full speed I place a nickel on the frame rail. A properly designed machine will allow the nickel to stand with the machine in operation. If it continually falls over you are pushing the machine too hard or the machine is not rigid enough. That means slower cutting speeds and much longer machine run times. That translates into more electricity costs and slower production times. I much prefer a heavy duty steel machine.

Then there is the matter of equipping the machine with an automatic tool changer or not. With our 3D work we typically use three tools (or more) per job. The work is first roughed out using a 3/8″ ball nose bit with a high overlap. A fine pass is then done using a 1/8″ ball nose bit. And finally I use a cutter to cut out the pieces. All this tool changing meant an auto tool changer made sense for us. It added a considerable cost to the machine but has paid for itself in the long term. There are also two options in auto tool changers. Linear style tool holders have the spare tools arranged in a holder at the end of the machine. A rotary tool changer is bolted to the gantry which means quicker tool changes as they are closer. I prefer the linear tool changer and there are less moving parts. Having the gantry travel to the end of the table to grab a tool doesn’t take very long.

Vacuum hold down was another option to consider. I quickly determined I didn’t want to fiddle with clamps or screws to hold my work in place. A quality vacuum hold down system was a must.

Spindle size (horse power) is another option to consider. I knew I would push my machine hard and so I needed five-eight horse power. Because we have single phase power and have to run an inverter I effectively lose up to thirty percent. So we opted for a twelve horse power spindle. Run times on 3D projects tend to be very long and so durability was a major factor. We opted for a spindle with four ceramic bearings. Air cooled versus water cooled is another option. Because we live in a temperate climate an air cooled spindle was deemed adequate.

Familiarizing myself with all of the terms and options for a CNC router took me a couple of months and many phone calls to both router manufacturers and owners. The internet also helped a great deal. After I had completed my research I knew the type of machine I needed.

Our new CNC router would have the following specifications:

Heavy duty steel construction throughout. Steel gantry with 6″ of clearance

All servo drive

Four foot x eight foot table

6″ minimum gantry height

6″ minimum gantry height

12 hp spindle with auto tool changer – linear style tool holder.

Vacuum hold down

Once I knew what I wanted it was time to actually start shopping. That’s for the next post…

Published with permission from precisionboard.blogspot.com. Source.