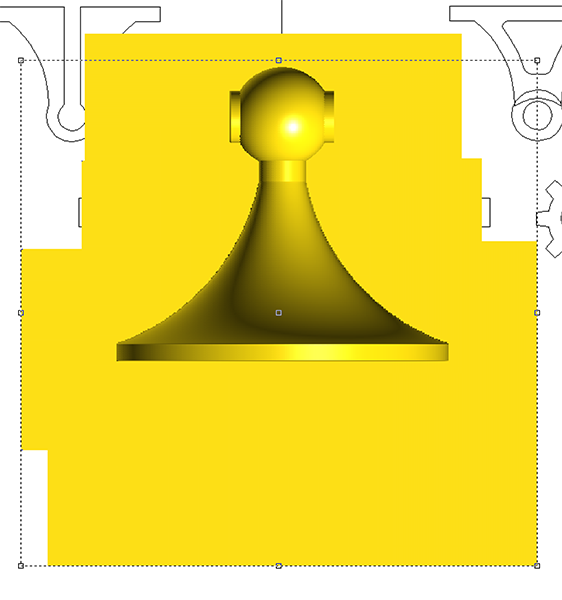

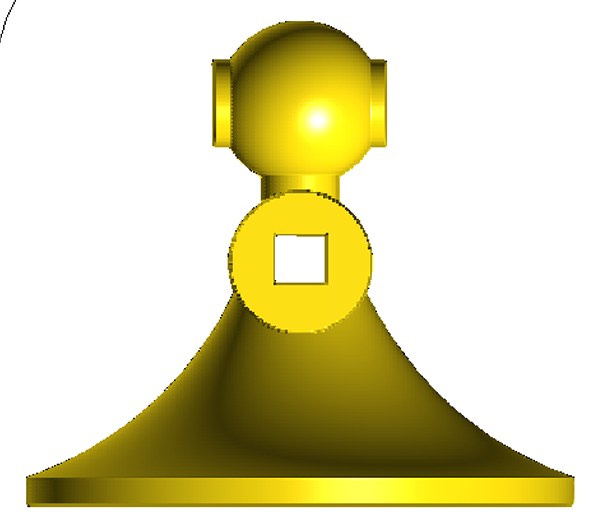

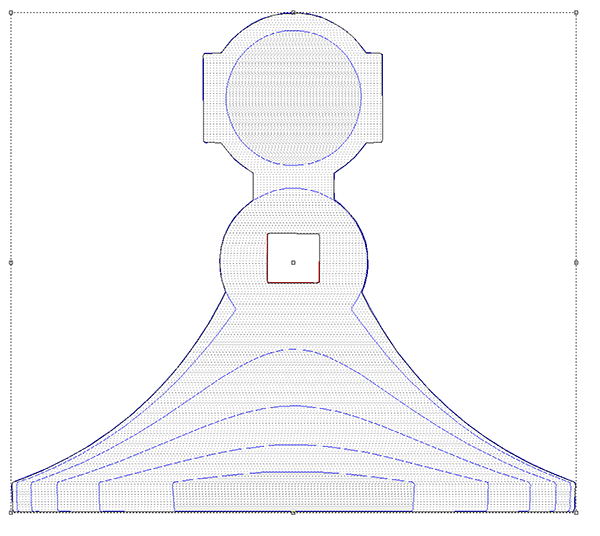

The upper portion and motor base of the lectern stand was a challenging piece to build. There were a number of ways I could have handled it but I chose to do it with a combination of domed reliefs and one mesh. The piece we were building today was shaped a bit like a funnel with a horizontal tube in the middle and a lightbulb shaped thing on the top. An axle would go through the top part for the big gears and through the horizontal tube (‘motor’) for the smaller gears.

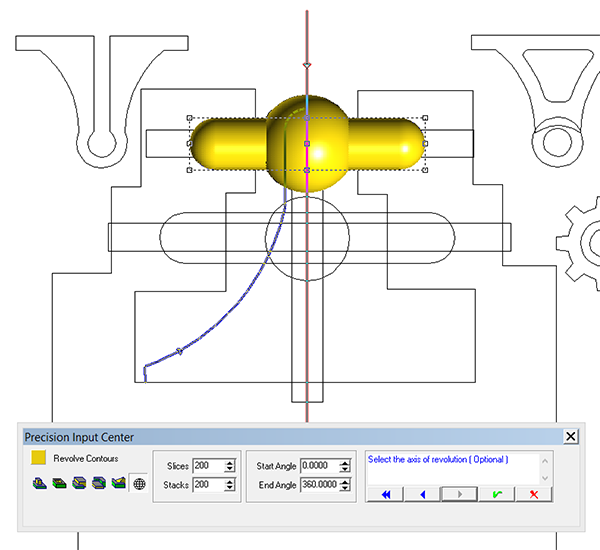

The round bulb was the first and easy relief using the dome tool.

The round horizontal shaft was next. Again I used the dome tool to create this relief. I would cut the rounded ends off later.

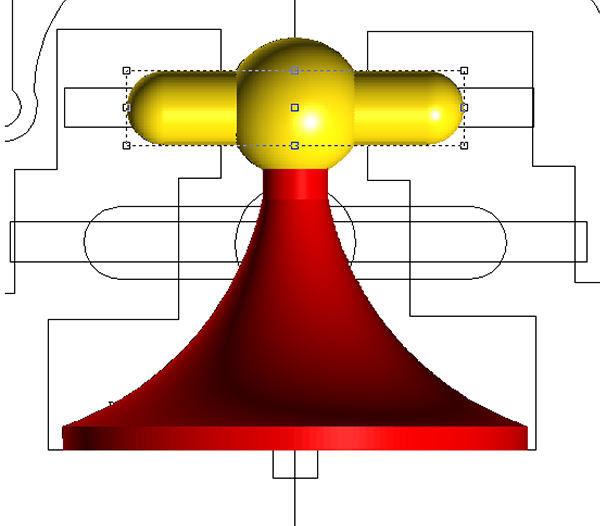

Next up was the side down funnel shaped base. The mesh tool was used for this shape. I drew out the vectors and then used the revolve tool to create the mesh.

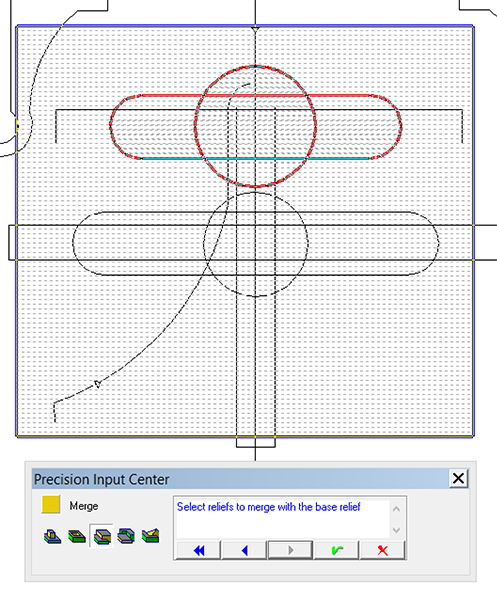

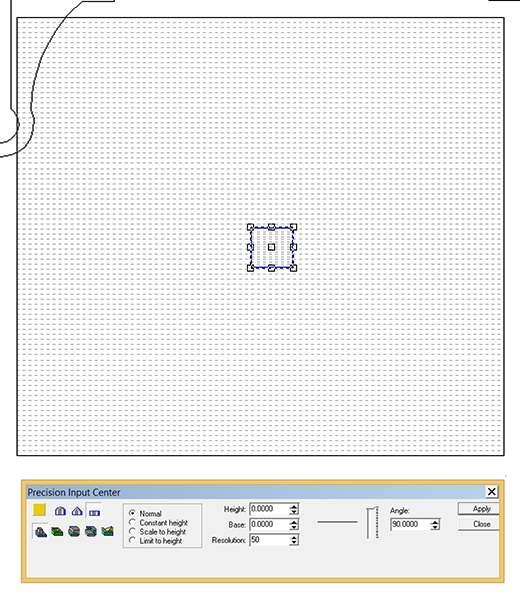

A square zero height relief was quickly created. Then I selected this relief and the mesh to activate the combine tool. The other oddly shaped zero height relief was also created at the same time. I would use this relief (merge lowest) to clip the ends of the hot dog shaped relief to a square shape.

I then selected this new relief and merged highest with the lightbulb and the hot dog shape.

I then created a round (flat topped) relief which would form the horizontal motor. This too would be merged highest with the rest of the relief.

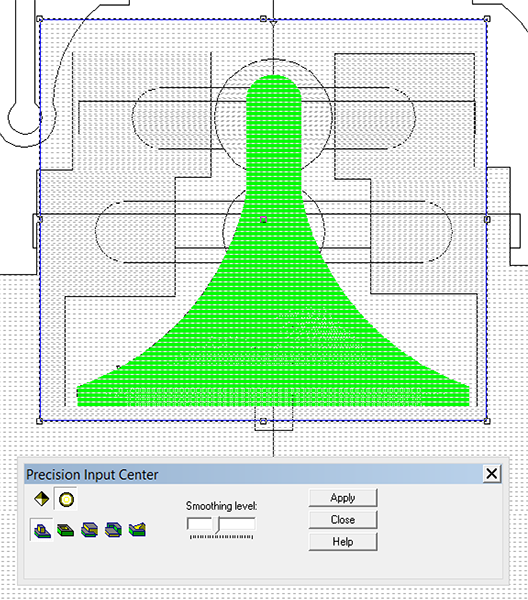

Since the horizontal motor would have some square tubing inserted down the middle I created a zero height relief for that and modified the base relief by merging lowest with that square shape.

The very complex shape was then finished. Now it was simply a matter of using the slice tool to create layers which would be routed singly and then glued back together after they were cut.