Out technical staff at Coastal Enterprises has received questions frequently in regards to using PB-Fast Set for edge bonding. Here is a quick step by step picture aided explanation of how it’s done.

This sample of PBLT-15 was cut into two pieces. Our goal is to use PB-Fast Set and bond the halved pieces back together without any gaps or separations.

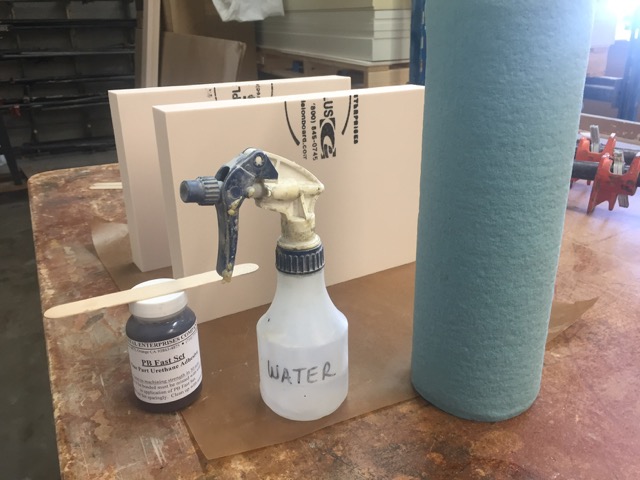

What you will need for this bonding project is PB-Fast Set, a spray bottle with water, paper towels or a shop rag, the Precision Board needing to be bonded, clamps that will fit the measurement of the Precision Board (we used pipe clamps), and a working space large enough to accommodate the project.

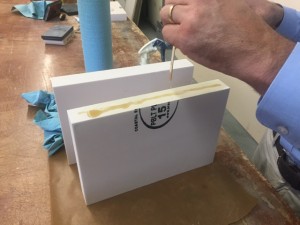

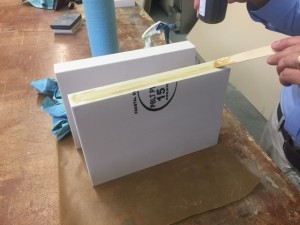

Place the two pieces of Precision Board in a way that the edges you want to bond are facing “up” or on top. You will distribute the PB-Fast Set on ONE SIDE of the two edges leaving ¼” of space away from the edge allowing room for the PB-Fast Set to expand. Spread the PB-Fast Set uniformally using a tongue depressor or brush.

With the spray bottle of water, mist the other edge needing to be bonded. This will activate the PB-Fast Set causing it to set up and secure the bond.

**NOTE** At the point of contact between the two edges being bonded, you will be on a bit of a timer. You have 4 minutes of working time, so you must work quickly to use your clamps and align/connect the edges.

We used pipe clamps to connect the two pieces. You may use any clamps you like that will securely hold the two edges together for a seamless bond line. Wipe excess adhesive off for an easier clean up.

At this point, you must allow a full 30 minutes of time to ensure the bond has fully cured. Once cured, sand the excess to a smooth finish allowing for a clean and tight bond line.

PB-Fast set requires no mixing, works well on wood, metal and most other materials. It’s easy to cut, carve, sand or machine, and cuts cleanly.

Find out more about PB-Fast Set and our other companion products here.