Landmark composites convention kicks off in Knoxville, Tennessee

The composites industry is constantly looking towards the future, providing the means and materials for the next groundbreaking technological advancement. Every manufacturer is racing to discover the next big thing, that next stepping-stone on the way to better technology, more effective production processes, and a higher understanding of our own capabilities. Tomorrow, hundreds of industry professionals and passionate hobbyists will convene in Knoxville, Tennessee for one of the largest meetings of the minds in the industry: CompositesWorld’s Carbon Fiber 2015. Throughout keynote presentations and tours of the Oak Ridge National Laboratory, attendees will focus on the expanding role of carbon fiber at the forefront of the composites industry, conferencing with technical experts from all over the world to envision the future of this particular composite.

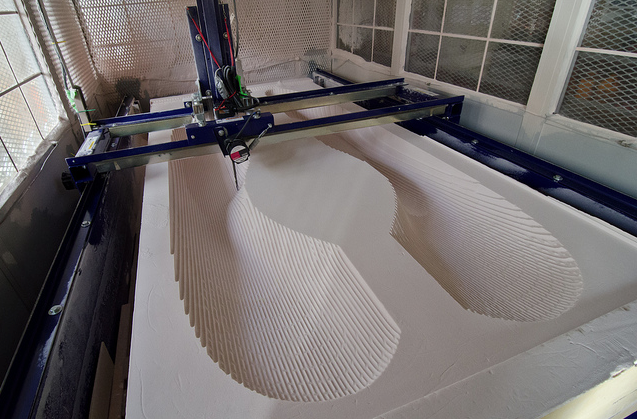

The Coastal Enterprises team is well aware of the possibilities inherent in carbon fiber, and we have worked tirelessly to ensure that we stay on the cutting edge of carbon fiber shaping processes. Precision Board can be machined or hand carved easily and cleanly, making it an obvious choice for producing layup molds of any shape. In addition, Precision Board is chemically inert and does not outgas when heated, allowing prepreg to be used without issue. Typical urethane tooling boards release byproducts that prevent the composite laminate adhesive from curing, but Precision Board can be heated without any adverse reaction.

Precision Board can accommodate any size mold design thanks to our custom bonded blocks. Multiple sheets of HDU (each up to 24 inches thick) can be permanently bonded together with our specially-formulated EP-76 epoxy to create completely custom shapes and sizes. The best part is, we perform this service in-house! This allows you to lower your material costs and conserve precious machine time by ordering a block of HDU in the specific shape you require. Rather than wasting time and money cutting away material you didn’t need in the first place, you can begin shaping your part as soon as it arrives. Precision Board lets you work smarter with carbon fiber, not harder.

Precision Board has always been a top choice for carbon fiber applications, and we look forward to enabling even more creative uses in the future. Check out some of the incredibly impressive projects made using Precision Board in conjunction with carbon fiber. But why stop there? Request a free sample today and see for yourself why Precision Board is the ultimate substrate for carbon fiber shaping!