Staying relevant in the modern composites industry requires a delicate balancing act of honest trial and error. In order to grow and mature, a manufacturer must identify the areas in which a product or process can be improved. This requires transparency and self-awareness; the will to acknowledge one’s own shortcomings and confront them in the open. We here at Coastal Enterprises believe that that no progress can be made without serious self-reflection, and we constantly strive to reinvent, to refine, and to reevaluate ourselves in the midst of changing times and shifting standards. With this in mind, we are proud to introduce a newly updated process for Precision Board Plus, a testament to our continuing commitment to adaptable excellence.

The processing changes we have made to Precision Board are based around our own careful study of industry trends and requirements, in order to more closely suit the needs of our customers. The new Precision Board features a tighter cell structure, providing a smoother surface finish and increased strength profile. No matter what the application, from low-weight signage and display construction to autoclave-cured tooling, stronger is always better. Whether it’s an exterior sign that needs to survive a harsh winter or a vacuum form/layup tool subjected to extreme temperatures, Precision Board has the durability you need for your specific project.

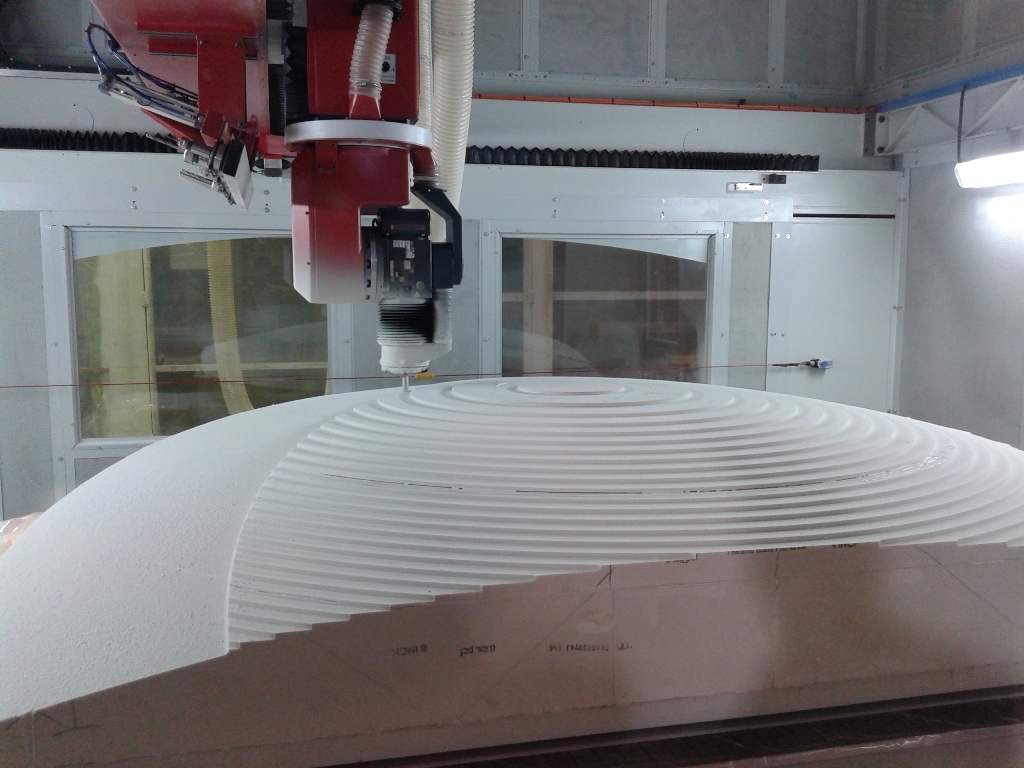

Another important benefit of our stronger, tighter, redesigned cell wall structure is the sharper edge machining we’ve achieved with Precision Board. It’s now much easier to dial in CNC speeds and feeds to control the router bit, to determine the amount of chips and dust produced while machining. Check out the short video above showing Precision Board being machined, producing mostly chips and little to no dust. Speeds and feeds were selected from the Onsrud router bit guide for machining Precision Board. Check out machining settings for all Precision Board densities to optimize your chip load.

All fifteen standard densities of our new Precision Board have a higher durometer, as well as increased compression and tensile strength across the board. We have standard densities ranging from 4pcf to 75pcf in both our PBLT (200°) and PBHT (300°) materials, with sheet sizes from 20”x60” to 5’x10’ and thicknesses from ¼” to 24”. With such a wide variety of densities, sheet sizes, and temperature tolerances, Precision Board can easily be adapted to most projects. But please, don’t take our word for it. Get your free sample today, and see for yourself how our new Precision Board can work for you!

Did you know: Coastal Enterprises constructs custom Precision Board mandrels to order? With the updated production process for our material, the quality and adaptability of our mandrels are top notch. Check out our recent blog post to find out how to streamline your filament winding process.