Signage professionals and followers of the Coastal Enterprises blog will know the name of Mark Roberts. As the owner and operator of The Intersign Group for thirty-nine years and counting, Mark is an undisputed master of the sign creation process from concept to installation. We like to think of Mark as the embodiment of one of our favorite mottos: “Why use wood?” He has proved time and time again that old standards shouldn’t be followed blindly, creating incredible dimensional signs with the look and feel of wood, but with the durability and customizability of Precision Board. Not only is HDU easy to work with, it is impervious to moisture, rot, termites, bark beetles, and many other environmental hazards that spell doom for a wood sign. Mark’s latest success story comes from Pasadena, Texas, where a local dental practice had its sign damaged by graffiti and asked Mark to design a replacement. Mark saw that their aging redwood sign wasn’t in great shape in the first place, so he decided to go with a material that he knew could stand up to foul weather and long, hard years of exposure: Precision Board Plus. Click here to learn more about The InterSign Group and see some of their amazing custom creations.

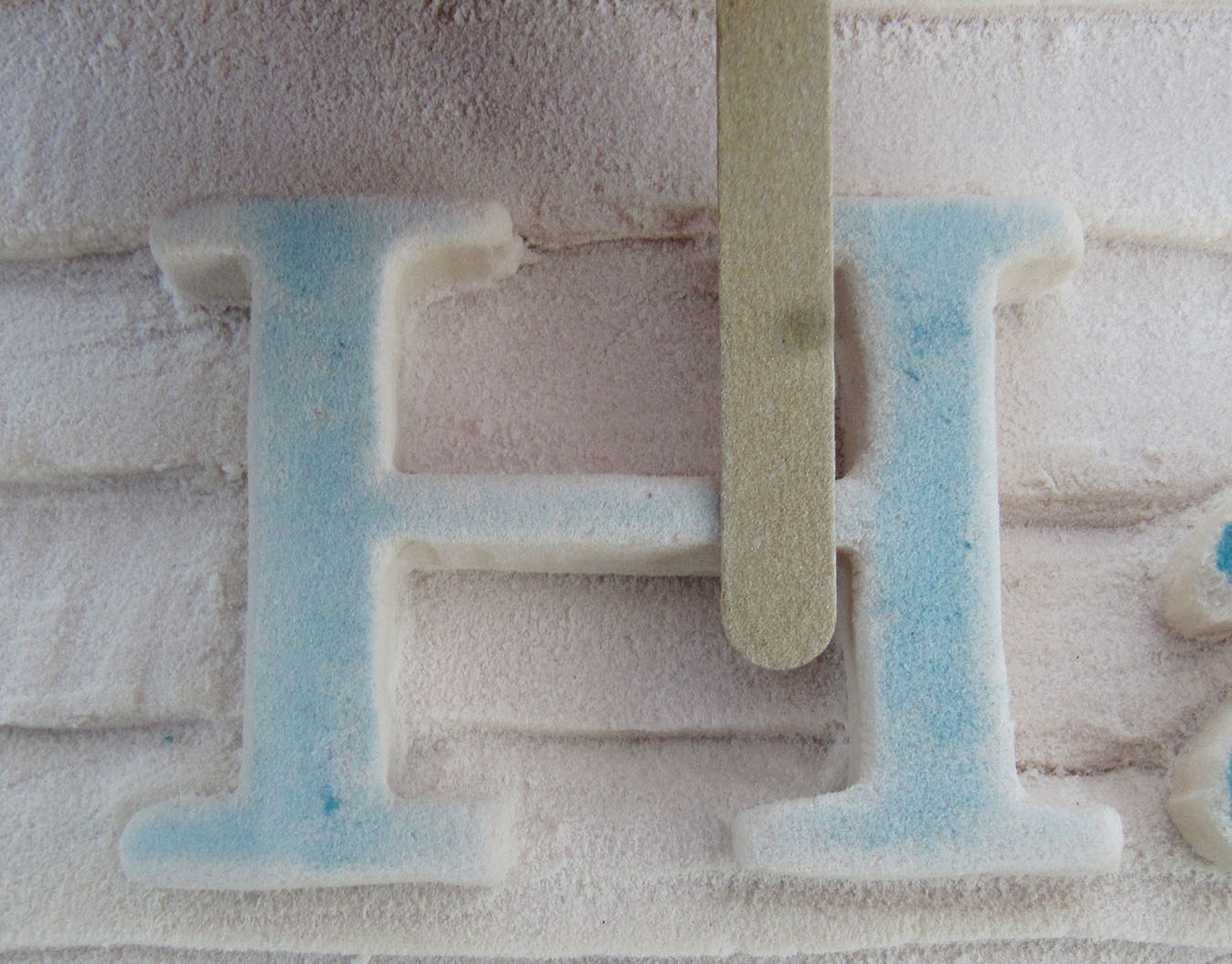

Mark decided to use 1.5″ PBLT-15 for this particular project, striking a delicate balance between durability, weight conservation, and cost-efficiency. We think he made the smart choice here; the versatile PBLT-15 is one of our most popular densities for signage, and for good reason. He started out by creating patterns for the sign text, then using his router and Dremel to cut down the surrounding material and create raised lettering. Mark likes to use an emery board to round out the edges of raised letters by hand, giving every sign a highly professional look and feel. At this stage in the process, Mark knew that this sign needed a little something extra, and he decided to go for broke: Instead of leaving a smooth background, he set to work with carving gouges and created a fully custom faux wood grain.

Mark creates his backgrounds with great care to make them as realistic as possible, and this time was no different: this was the longest step in the process, but the most worthwhile to the overall project. Check out our blog posts on sandblasting and using our Textured Surface Finish for other ways to create a natural faux wood grain.

The background was finished, and now the sign needed painting. Mark started off by applying two thin coats of our FSC-88 WB primer to every surface of the sign, and allowed them to dry thoroughly. Afterward, he painted the sign with a latex semi-gloss, a good choice for any exterior signage. After applying a muted beige paint to the letters and borders with a sponge brush, the sign was all but finished.

The only step left was installation. Mark and the InterSign team dug two holes 30″ deep, lined the holes with Sonotube concrete forms, and inserted the sign posts. They carefully added the bags of concrete, simultaneously agitating the concrete and adding water to ensure a rock-solid foundation. Finally, they bolted the finished sign face to the embedded posts, a process made much easier by the relative light weight of the PBLT-15.

There you have it, another incredible signage project by Mark Roberts and The InterSign Group. Every time they complete a project like this, they prove once again that wood is not required to create an elegant, classically-styled sign. All you need is a creative spirit and a steady supply of Precision Board! Click here to learn more about The InterSign Group and see some of their other brilliant HDU creations, and check out the article Mark wrote about this project for Sign Builder Illustrated. Ready to start crafting your own faux wood masterpieces? Click here for a free sample of Precision Board and get ready to modernize your dimensional signage!