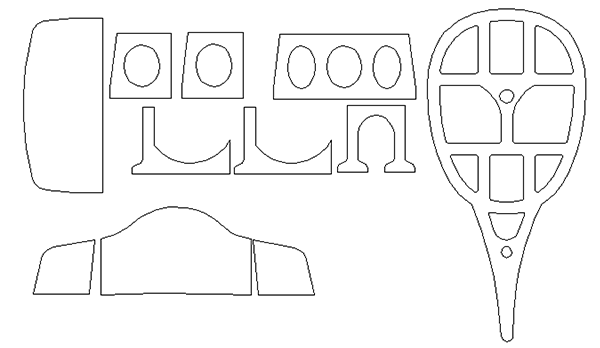

Even though our shop has limited metal working tools there is little we can’t accomplish with a little head scratching and ingenuity. I had great fun figuring out how to design, cut and fit the many pieces together to craft the little passenger rail car. In this case I didn’t even need a sketch but instead designed as I went, imagining how it would all fit together. Once the vector drawings were done I sent the files to the MultiCam for cutting. The lower sections were cut from 1/4″ steel plate and the top seat riser was done from 1/10″ thick steel plate.

To keep things simple I used a 1/4 section of 6″ steel pipe for the back corners of the seat. It was much easier to weld those pieces in than bend up that tight a radius by far. I bent and welded a piece of 5/8″ steel rod along the top to provide strength and provide a rounded edge to make it safer. I have a few more welds and a little grinding to finish this thing off. Then it is time for a test run!