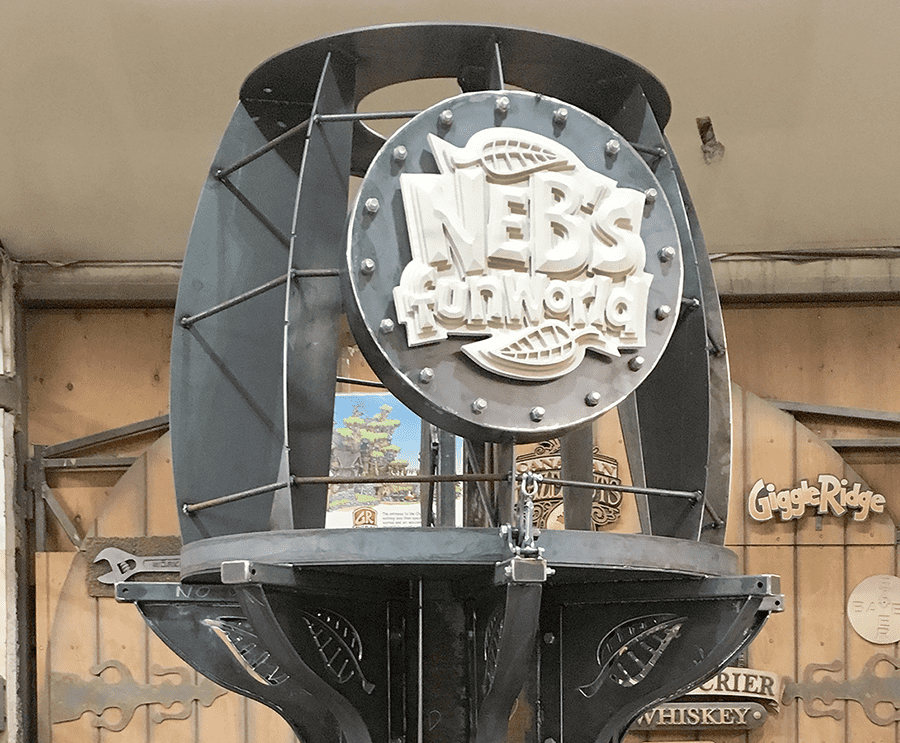

Coastal Enterprises, manufacturers of Precision Board HDU, is proud to announce a series of guest blogs written by Dan Sawatzky of Imagination Corporation, which will be posted on the Precision Board Blog at the end of each month. In this month’s entry, Dan has a fun project for a pub in Ontario, Canada. They are doing five good sized pieces including two giant barrels and two stills. The stills are for decorative and story telling purposes only. They are made from PBLT-30 Precision Board and plasma cut steel. While the sign portion made from Precision Board is relatively small compared to the whole project, it can add a great deal of detail and pizazz to any project!

We’ve been keeping very busy in our shop of late with many creative projects.

I designed the project using EnRoute Pro Software. I find this program great for design work as I can accurately determine the scale of the various components. Cut files were created at the same time for the plasma cut steel and routed Precision Board.

I then imported a screen capture of the EnRoute file into Adobe PhotoShop to create the rendering which was shown to our client for approval. With the approvals and 50% deposit in hand it was time to get to work!

There’s a whole lot of plasma cut steel in this project! Each of the two stills used nine sheets of 1/4″ thick steel plate. These pieces were welded to a 20″ diameter steel pipe that I had cut in half. The two halves of the still will break apart for shipping and then be rejoined around steel columns in the pub.

Pieces of 3” x 1/4” flatbar were hand formed and then welded to each rib of the uprights. The leaf portion of the logo was cut into each rib. Each still has more than two hundred lineal feet of weld! I know because I personally did all of it!

Once the center section of the still was fabricated we added the top barrel armature, then hoisted the assembly and slid the prefabricated bottom section under. The top barrel and lower section of the still will be hand sculpted using a thin shell of fibreglass reinforced concrete. I also welded a small circular table on at 42” off the floor.

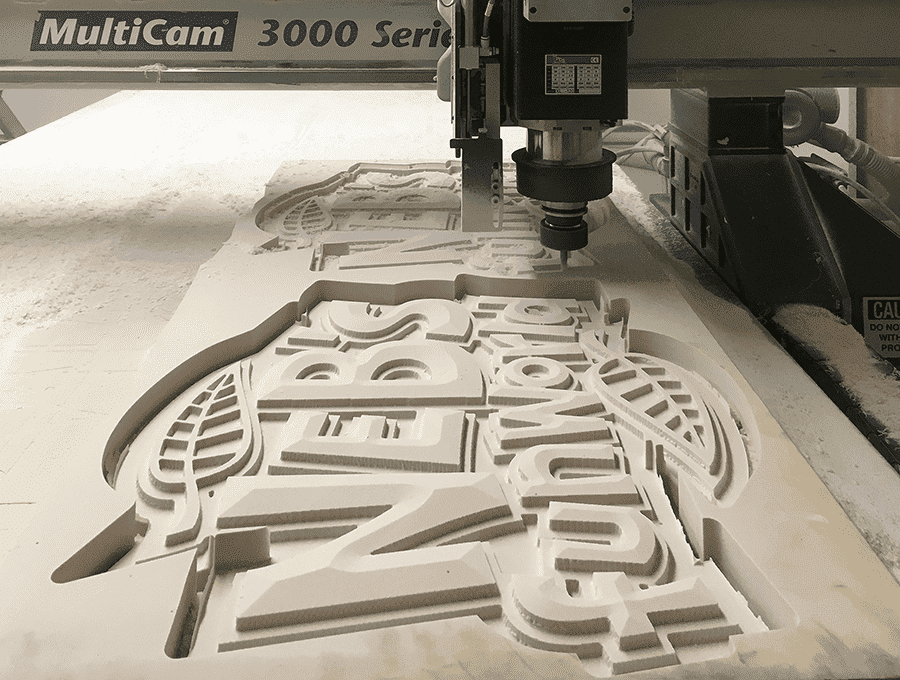

While I was busy welding all that steel our MultiCam was busy routing the dimensional logos from some 2” thick 30 lb Precision Board. The logos look great, even while they were still on the router! They will look even better when they are all painted up nice and bright in the pub colours! We will ask our client to do some custom lighting to make them really pop!

I then laminated a round piece of 3/4″ plywood to the back of each logo. We then attached the logos to the stills by using wood screws from the backside. They will be painted in place.

This piece is all about detail and so we fabricated eight barrel hold downs from plasma cut steel and a variety of hardware. These will be welded all around the barrels.

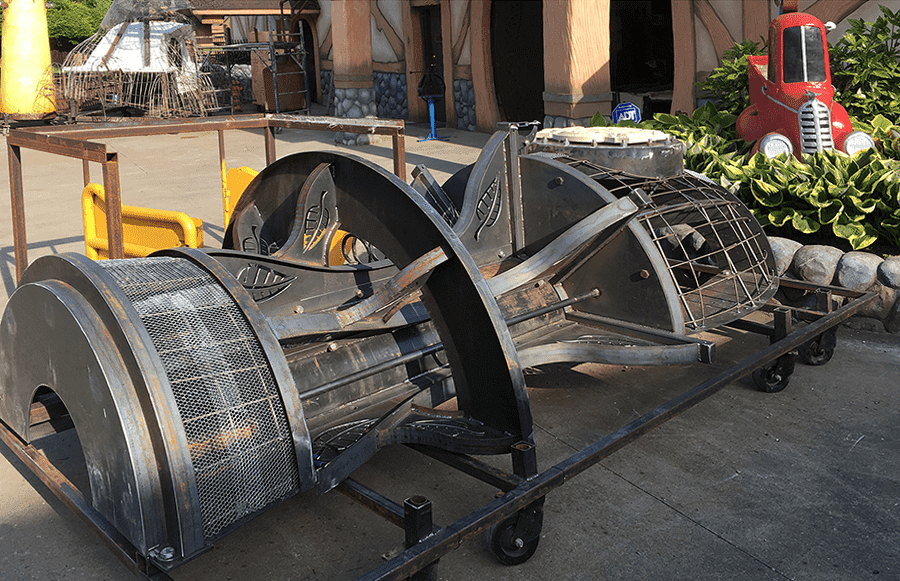

As each still is complete we are unbolting the two halves and gently laying the heavy pieces down onto a custom welded steel frame. These frames have sturdy wheels mounted so we can wheel them around our shop as we work on them. They will be shipped to the customer on the frames.

The second still frame is almost complete and the giant barrels are already in the paint stage. It won’t be long until we load these pieces into the semi and send them down the road to their new home.

Sawatzky’s Imagination Corporation is a small family company that specializes in the design and creation of dimensional signs and environments. They tackle projects of any size from small signs to entire theme parks. Their work has garnered numerous national and international awards.

Dan Sawatzky is best described as a creative force and visual storyteller extraordinaire. His art career spans almost fifty years of magic. Dan’s passion is to design and create imaginative places that take people from the normal world to a setting of delight and wonder.

You can get free samples of Precision Board HDU, request a quote, and sign up for the monthly Blog Roundup from Coastal Enterprises.