Kendal Signs has fabricated about fifteen signs for the City of Cocoa, Florida over the last several years. What originally started as cedar signs are now being replaced with Precision Board HDU after the harsh Florida weather damaged them. In this blog, Anna Johnson with Kendal Signs talks us through routing and sandblasting PBLT-15 Precision Board HDU and then attaching aluminum to the back for support due to the large size of the signs.

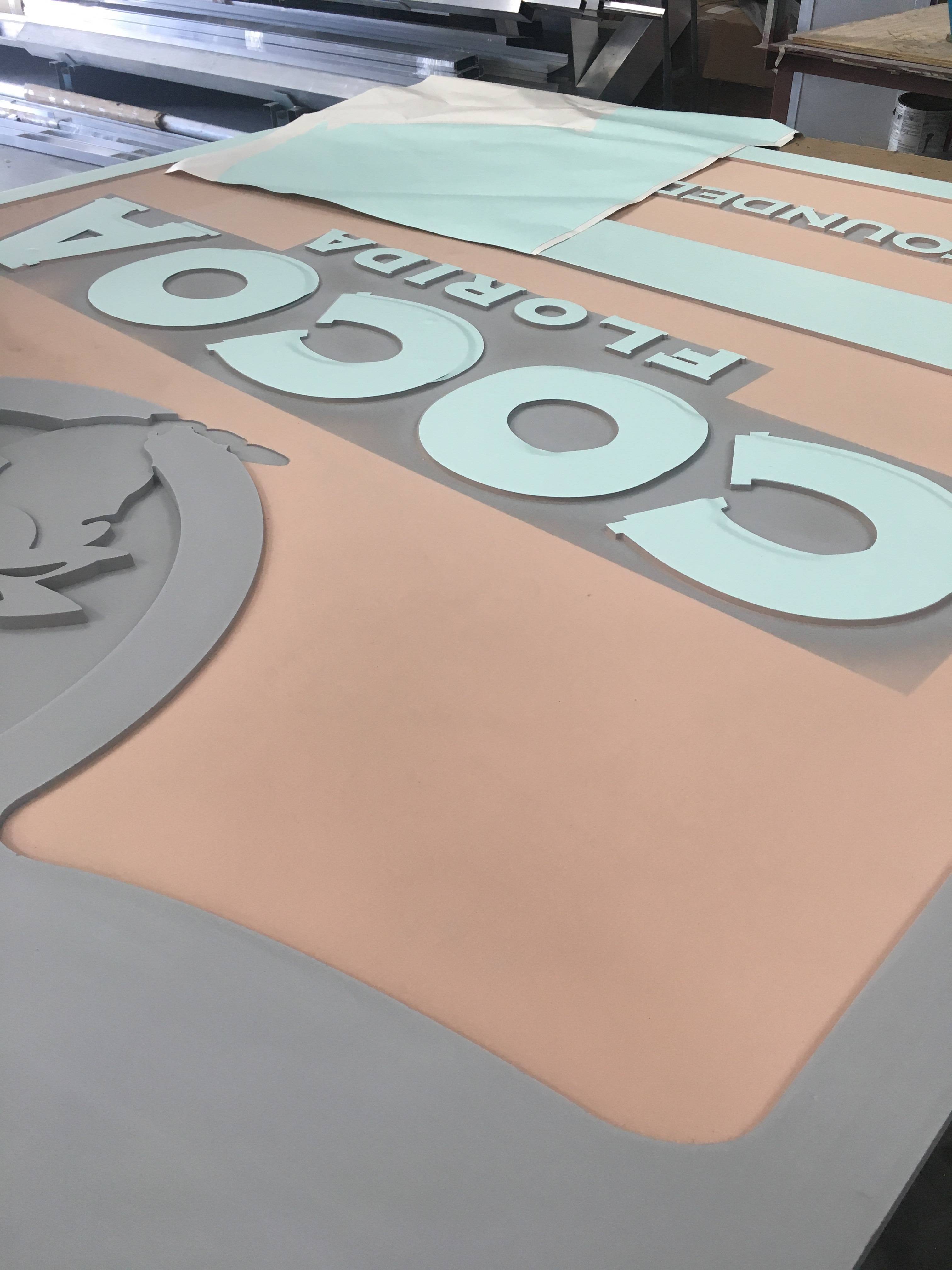

Anna used 1 ½” thick 15lb Precision Board to create two signs for the City of Cocoa. Kendal Signs designed the original signs for the city using cedar planks per the client’s request.

“It has been a few years since those signs were installed and they have been damaged by hurricanes and the harsh Florida climate, so we are replacing the wood signs with HDU,” says Johnson. She adds, “with Precision Board, you don’t have to worry about rotting.”

With the dimensions on the two signs being 5’10” wide by 7’6” tall and requiring multiple pieces of material, they had to be glued together and backed with .125 aluminum for added support. Additionally, the overall sign is 17’ above grade.

Anna tells us, “we used an expanding urethane adhesive for the seam and clamped the pieces together.” She adds, “the aluminum was then epoxied onto the back of the sign.”

Powder coated metal poles were specced because of the weather and the material’s ability to keep moisture out of the sign. Z-brackets were put on the back and U-bolts installed onto the back of the sign. They then mounted the sign to the poles.

The signs were then masked off for sandblasting followed by a topcoat of Mathews Paint.

“We used a sandblast mask and applied it to the HDU,” Johnson says. “Then we put a wire grate over it to give it a wood grain look.”

They operated the sandblasting machine at 80 psi and took about 5-10 minutes per sign.

Anna likes using Precision Board HDU because she can get a nice finish on it and doesn’t have to deal with weather-related issues like rotting or warping. “It’s not like some boards that are more porous and chip away. It’s cleaner.” She adds, “the quality is better, so it makes for a nice clean product.”

She offers this advice for working with HDU.

“Make sure the material is primed and prepped so you get a clean and smooth finish.”

In January of 1996 Kendal opened a small sign shop in Rockledge, FL and today has become a leader in the industry. Kendal Signs is now Brevard’s largest sign shop with an account portfolio that spans across the country. In addition to fabrication and installation, they service and maintain all types of signs, including electronic message centers. Tackling a job from start to finish gives them an edge over the competition. Kendal Signs is pleased to be a full service, state certified contractor, and a MET Labs Approved and Inspected Sign Manufacturer. You can call them at 321-636-5116 or visit their website.

Kendal Signs has recently purchased Daniel’s Wholesale Sign Superstore to help meet the signage demand industry-wide. Sign companies now have the ability to order signs online through their website.

Coastal Enterprises manufactures Precision Board HDU, a versatile, cost-effective and eco-friendly urethane sign material that is particularly effective for making professional-looking indoor and outdoor dimensional signs. It is a closed-cell rigid substrate that does not rot, warp or crack. You can request free samples, get a quote or sign up for periodic newsletters packed with helpful information.