National Composites Week is designed to introduce young people and others in the community to the composites industry, the career opportunities available, and demonstrate the contributions composites make to the local, national and global economy. Coastal Enterprises manufactures Precision Board, a high-density urethane tooling board used extensively in composites, including industries like aerospace, automotive and marine and in a variety of applications including molds and prototypes.

We’ll be sharing various ways that Coastal supports composites throughout the week.

Today’s Topic: Coastal’s long history and roots in the space program

A young Chuck Miller started his work with urethane on the Saturn stage II rocket. It not only launched a rocket to the moon, but it eventually launched Coastal Enterprises. The Space Program has informed many of the product innovations over the last 50 years, including Precision Board urethane tooling board and our line of companion products, which includes adhesives, primer, and textured surface coatings. Read on to see where it all started and to learn a bit more about the deep history of Coastal Enterprises and NASA’s space program.

Chuck Miller, President of Coastal Enterprises, was featured on the Composites World podcast last year. He discussed his background and involvement with the evolving world of composites and tooling from his time as a Manufacturing Engineer on the Saturn S-II, the second stage of the Saturn V Moon Launch Vehicle (fabricated by North American Aviation in Seal Beach, CA) through the founding of his company, Coastal Enterprises, and into what the future may hold for composites. You can listen to the podcast as well as check out the blog post that Composites World did.

Coastal Enterprises is a privately held company founded in 1973 by Mr. Chuck Miller, President, after his participation in the Saturn S-II Space Program at Rockwell International. The Saturn Launch Vehicle used polyurethane foam as its exterior fuel tank insulator, and it was at this time that his experience with this unique material began.

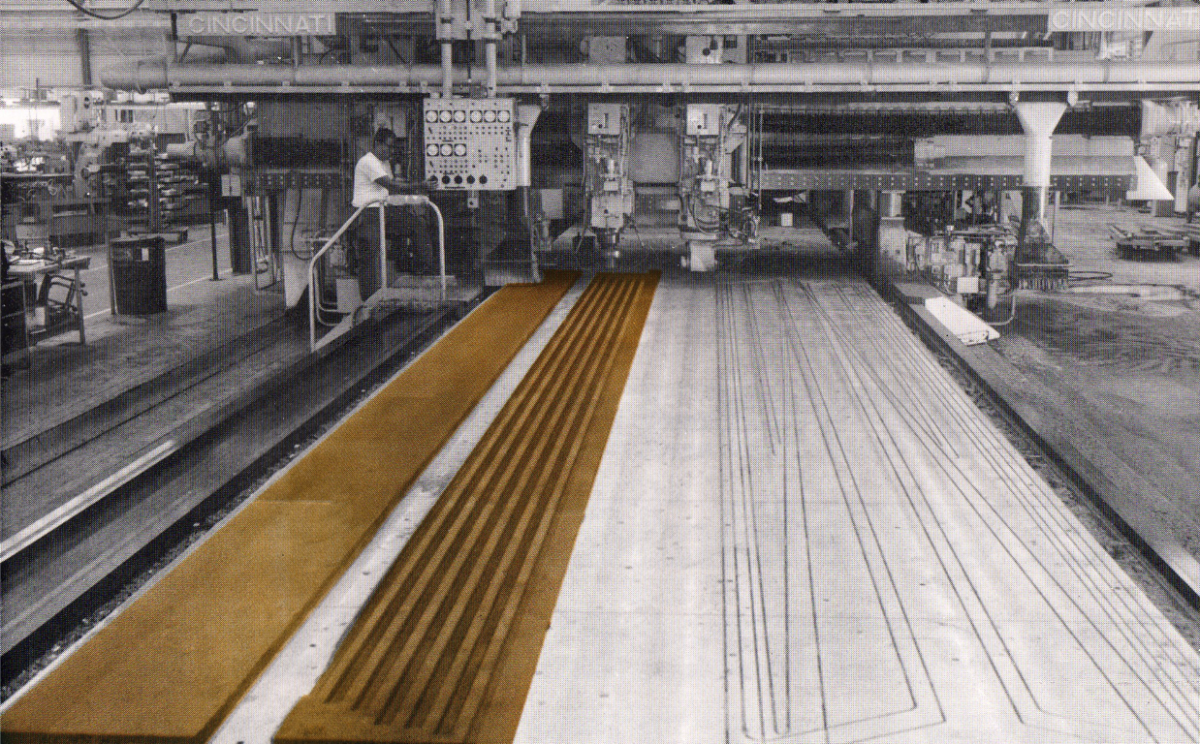

Products manufactured by Coastal Enterprises and sold internationally in 1973 were primarily for the machining industry. At the time, they were high density urethane blocks used to “proof” computer programs on numerically controlled milling machines. Ease in machining and lower cost made urethane the preferred choice over proofing on the actual steel used for the part being machined.

Initial development of Precision Board began in early 1989. By redesigning the chemical formulation and manufacturing methods of our original machining product, Coastal Enterprises developed Precision Board High-Density Urethane Tooling Board with physical characteristics to meet the rigorous demands of aerospace tooling and the machining standards of today’s 5 axis milling machines alike.

This non-abrasive, easy to cut and easy to finish material continues to be used extensively by the aerospace industry to this day for everything from prototypes to composite layup tools. After years of development and understanding of industry needs, Coastal now offers custom-bonded step-tools, a proprietary bonding process which results in bonded blocks made in near-net shape configurations with nearly imperceptible bond lines. As we continue to grow, our material is now being used in a variety of industries, including aerospace, automotive, government, military and bio-renewables.

As the next generation of engineers and designers are now entering the composites industry, we are excited to see how they will use Precision Board Urethane Tooling Board to help move composites to the next level.

National Composites Week Schedule

Monday- Coastal’s School Donation Program

Tuesday- What is soft tooling and how has it changed the composites industry?

Wednesday- The benefits of Precision Board over other tooling boards

Thursday- The creation and benefits of Precision Board step-tools

Friday- Coastal’s long history and roots in the space program

A group of composites industry leaders has announced the creation and launch of the inaugural National Composites Week, Aug. 26-30, 2019. The goal of National Composites Week is to encourage manufacturers from throughout the composites manufacturing supply chain — raw material suppliers, convertors, designers, toolmakers, fabricators, educators, students — to celebrate and bring attention to the myriad ways that composite materials and composites manufacturing contribute to the products and structures that shape the American manufacturing landscape today. More information is available HERE.

National Composites Week was organized and launched by braiding specialist A&P Technology, global advanced composites company Hexcel and media partner CompositesWorld magazine.

Coastal Enterprises manufactures Precision Board, a versatile, cost-effective and eco-friendly urethane material used extensively in the tooling industry. It is a closed-cell, rigid, dimensionally-stable substrate that is ideal for use in a number of different tooling applications.

Request free samples, get a quote or sign up for weekly e-blasts packed with helpful information.