Coastal Enterprises, manufacturers of Precision Board HDU, is proud to host guest blogs written by some of the signage industry’s biggest movers and shakers, posted to the Precision Board Blog. Adam Carlson with CNC Tahoe wanted to do a fun project, so he created a topographical map of the surface of the planet Mars, using 15lb Precision Board high-density urethane. Below he walks us through the steps, including speeds and feeds settings, and shows us the finished product!

In Adam’s own words…

Mars.

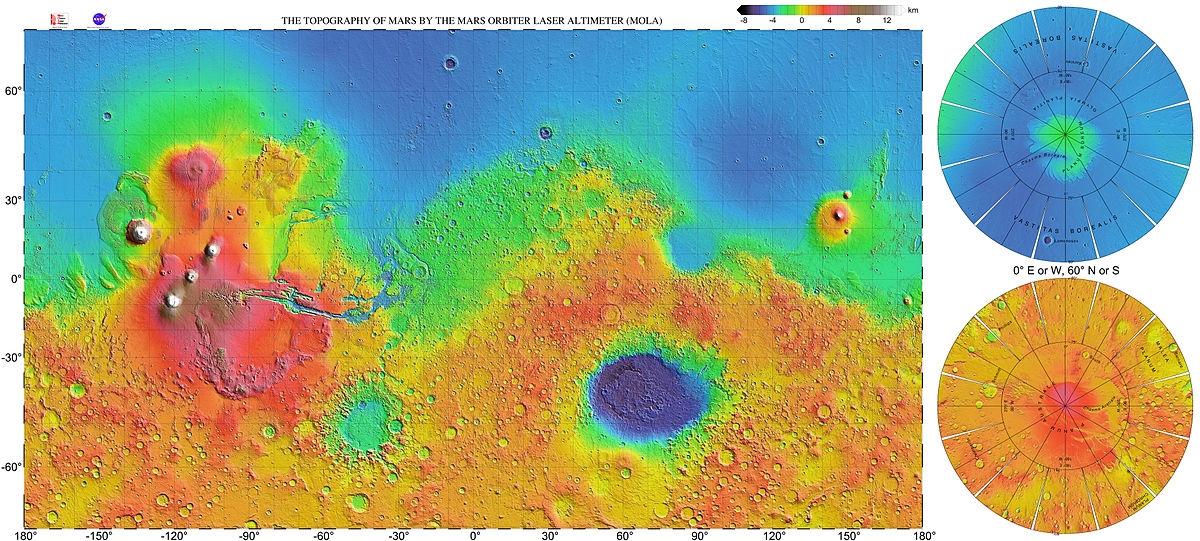

This was a random project I wanted to do. I never seem to have “fun project” time, and had a small window, so I seized it. First I took a topographical MOLA dataset of Mars surface from NASA, converted it into a grayscale height map, imported it into Aspire, created the CAM file and then exported it to my Shopbot Buddy.

I secured the Precision Board (PBLT-15) sample from Coastal Enterprises to the spoil board with some CA glue. The PBLT-15 was factory flat and sat flush on the table. The small chunk I removed was easily done on my bandsaw, the Precision Board cut like butter! Next I zeroed out Amana Tool #46282-K I received from Tools Today. Normally on topographical carvings I zero to the table but It wasn’t necessary since I only had to run one file. Since the PBLT-15 is a lower density and cuts smooth, I was able to run the 4 flute, 1/16″ ball nose bit for a finishing pass right away and at a faster than normal feed rate.

The large “bump” is Olympus Mons, the largest volcano in the solar system. Towering 16 miles high, 374 miles in diameter and surrounded by a 4 mile cliff. Roughly as large as Arizona and 4 times taller than Mount Everest…now that’s big. I love how the Precision Board gave high detail on the surface, which is easy to see in the right light, and the 15lb. density is good for topographical testing, holds great detail and can be cut at faster rates.

This 4″ x 8″ x 1″ piece was machined in approximately 3 hours at 195 IPM feed rate, 165 IPM plunge rate and spindle running at 18,000 RPM. Using an 11.1{afbea94bd31582343c3017644f03ec8d7d8fa2386ecb82c250661e06c0c6e111} (.0069″) step-over to keep the detail fine and tool marks zero made for a clean outcome, but a longer cut time. For topographical carvings, true end products, I’m sticking with 30lb and up, though. PBLT-15 is a recommended density if you reference the Precision Board Material Selection Guide (Ed note: suggested densities for topographical and architectural models on our chart range from PBLT-10 all the way up to PBLT-75), but I like dense material for a final product. This was perfect for prototyping.

My next project is a topographical map of another location. This time near central California and will be done using PBLT-30. Follow me on Instagram to see the next story very soon. Also, I have another idea in mind. We’ll see if we can make this one a reality with Precision Board HDU!

Adam Carlson runs CNC Tahoe, a shop where he does design, woodwork and machining. He also runs PLUS Skateboards. You can contact him via email.

Coastal Enterprises manufactures Precision Board, a versatile, cost-effective and eco-friendly urethane material used extensively in the tooling industry. It is a closed-cell, rigid, dimensionally-stable substrate that is ideal for use in a number of different tooling applications.

Request free samples, get a quote or sign up for weekly e-blasts packed with helpful information.