Coastal Enterprises, manufacturers of Precision Board HDU, is proud to host guest blogs written by some of the industry’s biggest movers and shakers, posted to the Precision Board Blog. This guest blog is written by George Leone, a long-time member of the Human Powered Vehicle (HPV) racing scene, and Team Captain for Team Primal. In this guest blog (part 1 of 3), George elaborates on the team’s progress towards fabricating Primal 3 using Precision Board and competing at the Human Powered Vehicle Speed Challenge near Battle Mountain, Nevada in September 2021 (this year’s event was cancelled).

Tom Robinson who helped me drive the truck and trailer, Matt Beccue does CNC work for Safran Aerospace & coordinated the project there, and Judy Lantaca, one of my favorite former Student Technicians at Cal Poly San Luis Obispo.

In George Leone’s own words…

After almost 5 years of chassis design and construction, precise aerodynamic design and computer simulation, we are poised to create the fairing for Primal 3, a streamlined, enclosed bicycle using 15 lb./cu./ft. Precision Board in the manufacturing process. This muscle-powered vehicle is designed for extreme speeds, far faster than you can legally drive on the freeway. A previous blog years ago featured Primal 2 which exceeded 70 mph three times using muscle power alone, on the flat road at the World Human Powered Speed Challenge held annually near Battle Mountain, Nevada.

We chose Precision Board not only for it’s great workability and consistency, but also for it’s high recyclables content. Our speedbike (also known as a Human-Powered Vehicle or HPV) is not only raced for records, but acts as a demonstration of what the future of transportation holds for us. Lightweight, extremely aerodynamic, structurally safe vehicles that use a minimum of effort to achieve energy efficiency. The recyclables content of the Precision Board used in its manufacture fits our futuristic agenda perfectly.

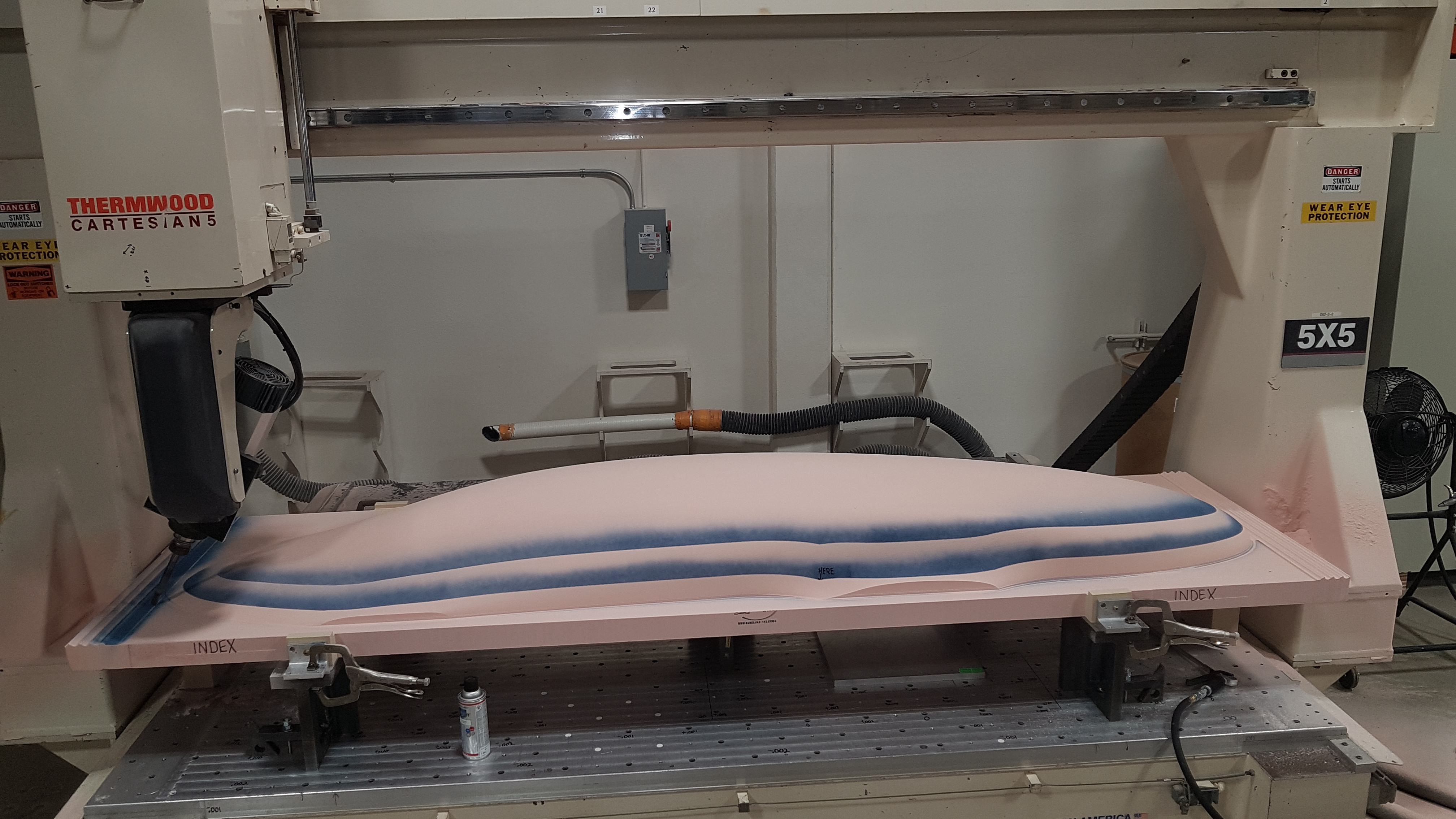

Pickup and transport to Safran Aerospace for CNC work.

We picked up two custom bonded blocks of foam for the right and left sides of the fairing in early March 2020. It was great seeing the clean, state of the art manufacturing facility that Coastal Enterprises runs. I used to run the Student Projects Shop at Cal Poly San Luis Obispo and always look at shops with a critical eye for cleanliness and safety.

The custom bonded blocks the we received had bond lines that were flawless, and the PB Bond 240 used as an adhesive that guaranteed there would be no “chunking out” of a hard adhesive, damaging the foam during the machining process. I’ve bonded a lot of foam in the last 40+ years and I was very impressed with the quality of the bond lines. From now on, I will definitely have Coastal Enterprises make custom bonded blocks for me. Not only does this save “gluing” time, it also saves re-work time to repair chunks of hard adhesive torn out by the CNC router or by the hand tools that I use.

My neighbor Jim McEntire, who restores tractors and vintage Ford cars, graciously loaned his pickup truck and a heavy duty trailer to bring the foam blocks to Safran Aerospace in Santa Maria, CA and from there home to my barn 4 hours North of Los Angeles, near Atascadero, CA.

We left Orange, California, the home of Coastal Enterprises, at almost rush hour and had to drive through Los Angeles. Somewhere in traffic in LA, I received a text from my friend and Cal Poly SLO Shop Manager, Eric Pulse, who I worked with for years. “So I see you’ve got the foam and are driving it North” !!! I replied “What the heck, how could you know this?” (I had not mentioned to anyone that I was getting the foam at that time.) Eric came back “Oh, a former student saw a truck towing a trailer with foam on it, and figured it was you. He thinks he saw you as a passenger.” (My old friend Tom Robinson was driving at the time). I swear, I could never rob a bank, someone would recognize me right away!

We delivered the Precision Board HDU three hours later to Safran Aerospace in Santa Maria, CA, as they had generously offered to CNC machine the aerodynamic body shape into the foam. Matt Beccue, the CNC supervisor, met us and we offloaded the foam and then drove the truck and empty trailer home.

The blue “Dychem” lines on the foam were done to verify the location of the surface as the project progressed.

Stay tuned for Part 2 and Part 3!

George Leone has a long history with Cal Poly San Luis Obispo and is a fount of knowledge when it comes to both composites and Human Powered Vehicle Racing. He volunteered sporadically helping Cal Poly’s HPV teams from 1980 to 1989, and then continuously from 1989 to the present. George also ran the Cal Poly Projects Shop from 2001 to 2017. This shop includes facilities for machining, student welding, woodworking, sheet metal work, advanced composites and design space for senior projects, as well as nine engineering clubs that compete at a national level. He has also built and raced his own HPVs since 1988.

ABOUT TEAM PRIMAL

Team Primal consists of a group of friends, current Cal Poly Professors and former students. It is privately funded and is not sponsored by Cal Poly in any way.

ABOUT COASTAL ENTERPRISES

At Coastal Enterprises, we like to look at the composites industry as a fully collaborative effort. Every fresh new development by an individual is really a contribution to a collective knowledge base. Like any scientific pursuit, the most potent advancements are made when information is shared freely between likeminded groups of people. For this reason, we feel obliged to do everything we can to enlighten and empower the future community of composites professionals. That’s why we support school programs with donations of Precision Board HDU. Click HERE to find out more about the program or give us a call with your questions at 800-845-0745.