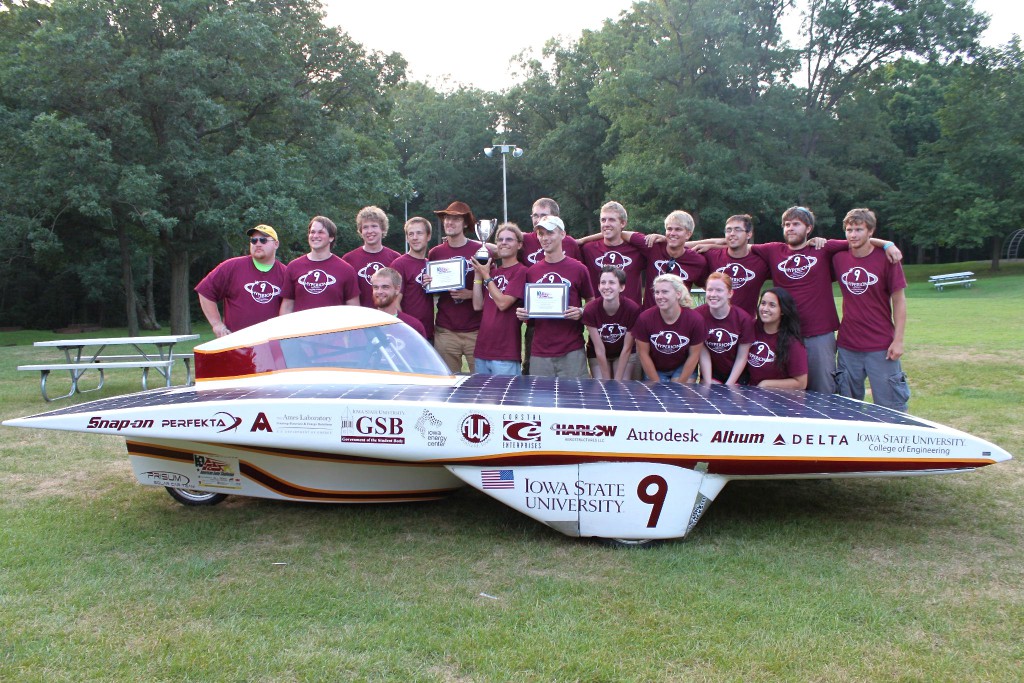

How soon will solar powered cars become a reality? This past July, the Iowa State University PrISUm solar car team raced their way to a second place finish in the North American Solar Challenge. Project Director Evan Stumpges took some time with us to explain a little bit about the PrISUm Solar Car team.

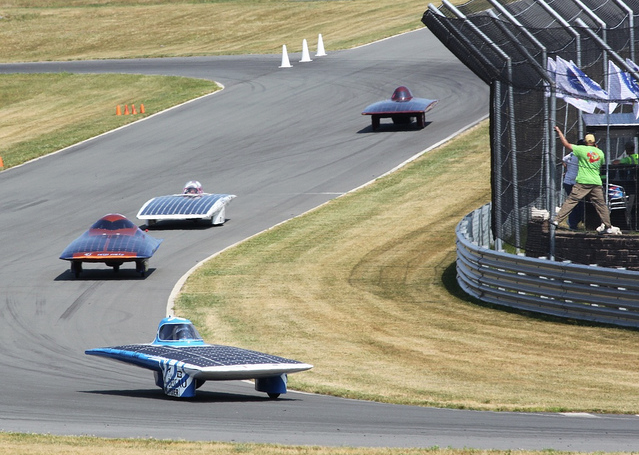

The North American Solar Challenge is an all volunteer project with each student team preparing for 2 years for the biennial NASC competition. Students design vehicles that run entirely off of solar power, which will clearly be a major automotive game changer should they ever go into production. The race spans thousands of miles over U.S roads, and consists of several timed stages between preset locations. This year the race started in Rochester, NY and finished in St. Paul, MN. To ensure a fair competition, each solar car is followed by an observer, and penalties are issued if the legal speed limit is not maintained. Speed is tracked by a GPS placed into each car.

As project director, Evan was personally in charge of designing the suspension system as well as acting in a leadership role to all of the other volunteers involved. Iowa State designed Hyperion to compete at the highest level of reliability in this years competition. Because many of the teams (16-18 teams typically compete) cars fail during the competition due to mechanical and electrical reliability issues, Evan says they placed a strong focus on building a reliable solar car that they could count on to make it to the finish line.

The end result was the Hyperion Solar Powered Car, which ended with a second place finish at the NASC, and best lap time at the Formula Sun Grand Prix (takes place at the Indianapolis Motor Speedway.) Hyperion was able to maintain highway level speeds throughout the entire 1650 mile competition and ended with an average speed of 65mph. Out of curiosity, we asked Evan if the car was equipped with any sort of A/C or heating system in case of harsh weather. It is not, although it does have a forced-air intake fan, which allows air to pass into the cockpit. The battery system is also equipped with cooling fans and is used in case of a storm or other solar panel failure, and will allow for travel up to 125 miles at 45mph. Hyperion had a total of 4 drivers, Evan being one of them, who traded off driving tasks through the competition.

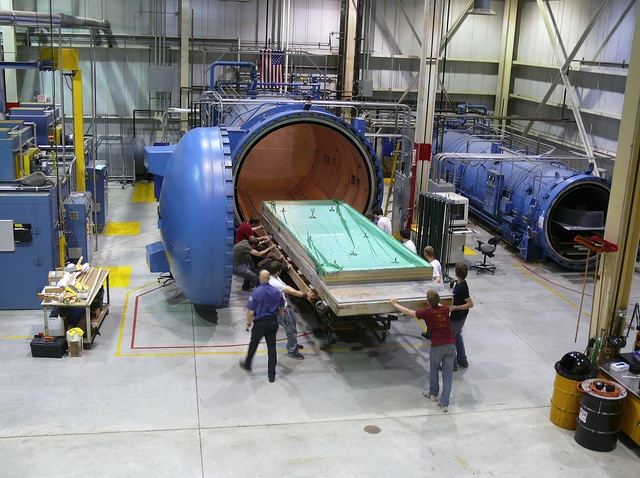

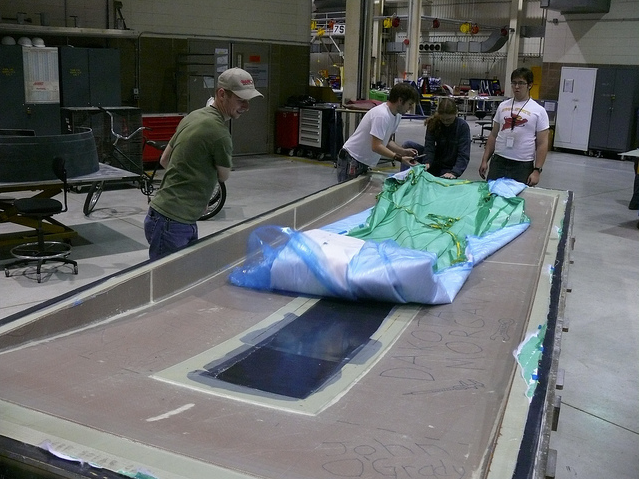

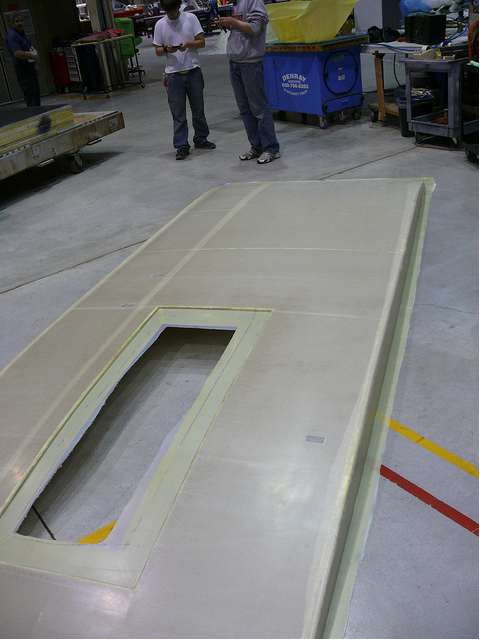

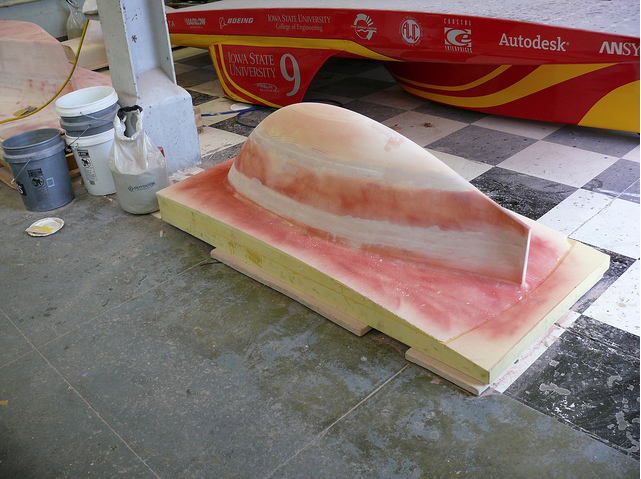

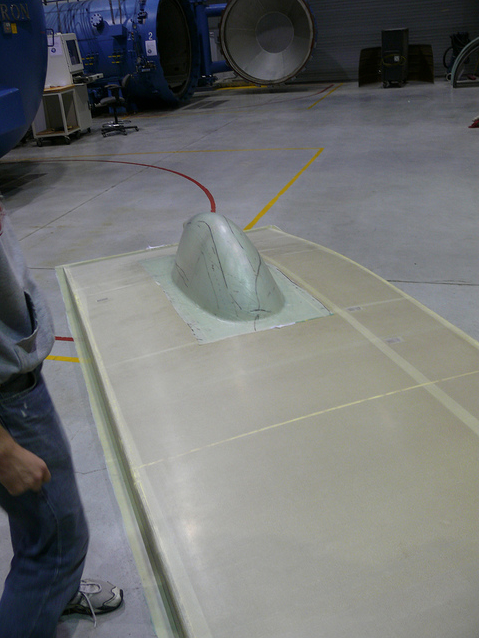

Coastal Enterprises has donated Precision Board Plus HDU to Iowa State University for mold tooling for the past 5 years. Evan stated that the variety of densities available and the minimal dust level were some of the reasons PrISUm and the company who assisted with the CNC machining, Harlow Aerostructures, enjoyed working with it. PBLT-18 and PBLT-20 were the typical densities used for these molds. Evan estimated the cost of this car to be around $330,000, and believes it would probably cost around $80,000 – $100,000 if in full production and depending upon which type of composites were used to produce it.

A recent Iowa State University graduate now, Evan is currently employed at a major machinery manufacturer as an associate engineer designing advanced electrical drivetrains. He attributes much of that to being a part of the all volunteer solar car team and specifically, the high level of discipline and leadership skills he attained while a part of the program.

Many more pictures can be seen here.

Also check out the Team PrISUm facebook page.

Pictures from the mold making process: