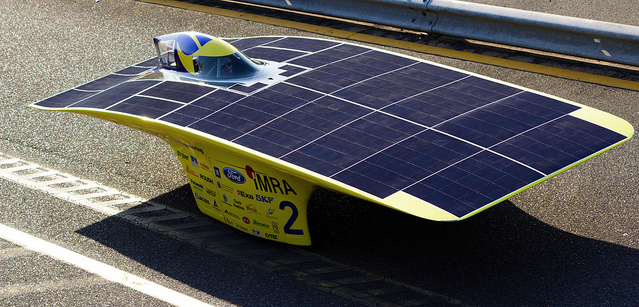

The University of Michigan Solar Car Program is leading the nation in the advancement of solar car technology. With help from major companies, including General Motors, the team is moving steadily forward to make solar cars a reality. They recently won their fourth consecutive North American Solar Challenge with the Quantum Solar Powered Car, and placed 3rd in the World Solar Challenge. All molds for Quantum were made using donated Precision Board Plus HDU.

The North American Solar Challenge is an intense 8-day competition spanning over 1500 miles, with the solar cars navigating America’s highways amid traffic. As an all volunteer program, over 100 students helped in the 2 year build process of Quantum. The very first solar car competition was held in 1990, and the first solar car winner (also University of Michigan) had a top speed of 24.7 mph. In comparison, the 2011 Quantum solar car can reach up to 105 mph! With allotted race hours from 9-6PM, Quantum finished 10 hours ahead of all the other cars under solar power alone in the 8-day competition.

We had the opportunity to speak with students Cole Witte, Engineering Director and Eric Hausman, Operations Team Member, about some of the details of Quantum. First off, the car does have a battery in case of a breakdown or inclement weather, and can go from 2-300 miles on the battery alone. There are no pedals and all acceleration controls are located on the steering wheel. Quantum was sponsored by General Motors this year, who provided an entire caravan of support vehicles.

When asked why this years car was able to perform so well, Eric stated that this year had the best aerodynamic design ever. They took full advantage of a free design consultation from Exa, a simulation-driven design company. For the most part however, the work is done entirely by students. Most of the students are mechanical, aerospace, electrical engineering or computer science majors.

There are 4 subdivisions within the engineering division on the team, and each are assigned to various systems of the car:

- Mechanical – Responsible for the design and manufacture of the structural components of the car (composites, suspension, brakes, steering etc.). Pretty much every point of the car will be touched by a mechanical engineer at some point in the construction phase.

- Aerodynamic – Responsible for designing and analyzing the outside aerobody of the car, making the most aerodynamic car possible.

- Power and Electrical – Work with all high voltage systems on the car, including the battery, solar array and motor.

- Micro Electrical – Design all of the low voltage control systems on the car, and write most of the software used across the car.

Here is an interesting interview with Cole Witte, Engineering Director for the 2013 project:

1. What is your role in the Michigan Solar Car team?

Cole: My role on the team is the engineering director for the 2013 project. As the engineering director I am responsible for coordinating the design, development and manufacture of the 2013 solar car. This involves working directly with over 50 engineers to ensure integration of all the vehicle systems.

2. How long have you been a part of the team?

Cole: I’m starting my 4th year with the team. I joined the team my freshman year in the fall of 2009 as a mechanical engineer, raced with the team in 2010 in the North American Solar Challenge, worked on the development and manufacture of Quantum, and traveled to Australia in the fall of 2011 to race Quantum in the 2011 World Solar Challenge.

3. Precision Board Plus was used to make molds for the Quantum Solar Car, how did the mold making process work?

Cole: For all of our large scale molds (vehicle, body, chassis, etc.) they used a 2 step mold making process. A positive pattern of the car is CNC machined from Low Temp Precision Board Plus, sealed and finish sanded. From there they use the pattern to create a fiberglass mold of the car. The mold is then removed from the pattern and used to create the final composite parts. For the small scale molds (wheel covers, ducting, electrical enclosures, etc.) we have the mold directly machined from High Temp Precision Board Plus, which we then seal and polish to the final mold surface. We use the High Temp Precision Board Plus for this process since the composite pieces are made using pre-preg materials and cured in an autoclave or oven.

4. What benefits did you notice by using Precision Board Plus?

Cole: Precision Board Plus allows us to get a very precise mold surface for our direct machined molds. Often times they come off the mill with a very finished surface that only requires final polish sanding. The dimensions and geometry are very critical with all of our parts, and with using the high temperature material we’ve never had issues with expansion or deformation even at high pressures in the autoclave. When it comes to the large patterns that we manufacture, being able to maintain a constant surface finish across the whole part is critical, with little to no change due to material variation.

5. This is Michigan’s 4th consecutive national win, and you are currently in the process of building the 2013 car. Will we be seeing any drastic changes?

Cole: There are definitely big changes in store for 2013. The World Solar Challenge has changed the regulations this year and now require 4 wheels (instead of 3), so it is a major game changer for all teams.

Additional information can be found on the University of Michigan Solar Powered Car Facebook page.

Many, many more pictures can also be seen on the UM Solar flickr page.