The old sign is down. It took about an hour and a half to get our steel bracket system installed and everything went together nicely. Best of luck Adam with your new sign – See you at Fetch! – Steve

KDF Custom Graphics Blog

Fetch Sign – Woof 6 (the final Woof)

It’s our last day with the Fetch Sign – we are finishing up the details and doing the final assembly. All the parts are painted so Peter now has to complete the pins and glue all of the elements in place – I’ll do a little welding and we should be done. We really want to make the collar ring look as real as possible so we shaped a 4′ length of steel rod inserted into the hole in the dog tag and welded a plate on it so we could easily secure it to the structure. We ran a bolt through the top of the sign to hold it in place.

Fetch Sign – Woof 5

All the parts are completed and they’re off to our paint shop. We use a PPG Waterborne Automotive Paint System which gets great results and is much less harmful to the environment. Holin, our master painter, has prepped the metal parts in our bead blaster, he then cleans them with a metal prep and they are ready for primer and paint. The foam parts are lightly sanded and we brush on a thick HDU primer.

Columbia University FSAE Team Car

Again another really fun project with our friends at the Columbia University FSAE team. What an impressive group of students! Check out their site here . We worked with the team engineers to create the molds for the cars body out of Precision Board HDU. The team then molded the carbon fiber panels. Once completed they sent us the panels for final finishing where our guys wrapped all of the parts in a black brushed metal vinyl. All of the logo and number decals were then created and installed. It really turned out great -Congratulations to the 2016 team and best of luck! Oh and thanks for the tie! – Steve

Fetch Sign – Woof 4

Today we are fabricating the interior frame of our sign. We are using 1″ Square steel tubing. We’ve pocket a raceway into the back of each sign panel. Peter is setting the steel pieces in place, we’ll tack weld them inside the sign for a perfect fit then take it out and complete our welds. Here it is all welded up and ready for assembly

Fetch Sign – Woof 3

Now it’s time to cut the elements that make up the face of the sign. The first element is the 3D bone which will have the Fetch name contour pocketed about an 1/8″ into the surface. Our rendering shows the layout and depth of the lettering. The bone is also carved out of 2″ HDU.

Fetch Sign – Woof 2

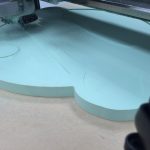

Files are ready! – our HDU is on the MultiCam table and we’re ready to cut. We are going to end up with a 3″ sign panel once the two halves are glued together so we’ve planed our 2″ HDU down 1/2″ then cut the face. We’ll insert out steel tubing, glue the panels together and our panel is done. Now it’s on to “The Bone”.

Fetch Sign – Woof 1

It’s an exciting day here at KDF. We were asked by our good friends at Fetch Bar & Grill in Warwick, NY to update their sign based on a new logo that was just refreshed by our favorite designer, Nanette Hoey . After some quick sketches we designed the internal frame that will be made from welded 1″ steel tubing – this will be incredibly strong and make for a very simple installation. Our files are created in Enroute Pro and prepped for cutting

Wright Family Farm Sign

We were very excited about this sign. Our friends at the Wright Family Farm in Warwick, NY needed to replace an old sign on the main road in front of the farm. This farm has been around for over 100 years so we felt very privileged to be involved. So we stepped in to help with the task by creating a new design that would incorporate everything they had to offer. Nanette jumped on the design and came up with a wonderful sign design that everyone was extremely happy with. Now we have to make it…