In the first two blogs in this series about picking a CNC router I discussed learning about router specs, picking the ones we needed and then selecting a manufacturer and dealer to supply our machine. I hear a great deal of talk about routers and how much they should cost. Some of my friends have bought routers from China. Service isn’t part of the package. When something goes wrong there is a steep learning curve to get the necessary parts and get things going again. I know people who want to do it all themselves, including building the router. I have no doubt they save money but they trade this money saved for the amount of time they invest. I maintain that time equals money and time is my most valuable resource. I don’t want to fiddle with my machine. I don’t even want to think about it. Other than greasing it as necessary and blowing off the dust I don’t do anything other than running it. Once or twice each year I’ll have a little maintenance done and occasionally the bearings need replacing. I let a knowledgeable and experienced factory tech do that work. I keep busy doing the work I love.

Choosing a top end router with top notch service didn’t come cheap. You get what you pay for. I didn’t endlessly haggle nor beat my guy down. I wanted a long term relationship with a friend that would take care of me over the long haul. And that I got.

Once we had negotiated a price it was time to figure out the terms to make sense of our purchase. My business plan indicated we could pay for the machine over two years. To be safe we decided to finance it over four. To be able to write off the machine quickly, we opted to lease the machine for four years with a small buyout at the end. Delivery, installation, setup, training, software and two years of service were negotiated into the deal.

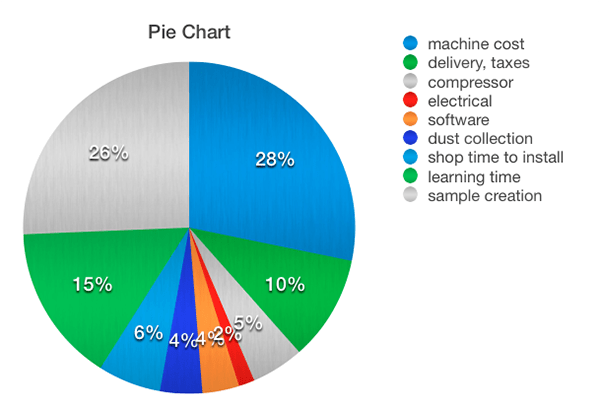

The price of the machine worked out like this…

My math includes everything. Please notice that even though we purchased one of the top machines (read that expensive) out there it amounted to only 28% of our total cost.

Delivery, duty and taxes amounted to another 10%. A good screw compressor with an air dryer added 5% more to the cost. Hooking up the electrical added 2%. The software was 4%. A good dust collector added 4%.

When we make a big addition like the router it is time to seriously rethink the production of the shop. We literally tore apart the whole shop, cleaned and rearranged everything to fit it in right. We spent the better part of a week at the task. At shot rate this added up to 6% of the cost of the router.

Most shops would total up the cost at this point. But we weren’t done. We could do little more than turn on the machine. We had to learn to use it to it’s best advantage. We also had to create samples of the new work we would do. Unless customers can see it they don’t buy it.

Learning the software meant investing time, starting with the basics. I had never operated any type of computerized equipment previously. We had to invest in ourselves. And that we did.

For two months we only produced samples on our machine. We started with the alphabet. This meant twenty six samples – all different. I learned about creating reliefs, making shapes, adding textures and a whole lot more. While we were at it we explored finishing techniques including paints, glazes and gilding. I filled our dumpster multiple times with things that didn’t work, and each time learned something new in the process.

Having one of the best machines in the world and not being able to use it is a poor investment. So we invested properly and counted all of our costs in the process. This meant we went in with our eyes wide open knowing we would come out the other side equipped to do anything imaginable. It worked!

Next time I’ll begin a discussion about software. Stay tuned…