Plate-All is a real, living (it ages just like real metal) metal finish that can be applied to virtually any substrate. The resulting finish looks and feels exactly like solid cast metal without the cost or weight.

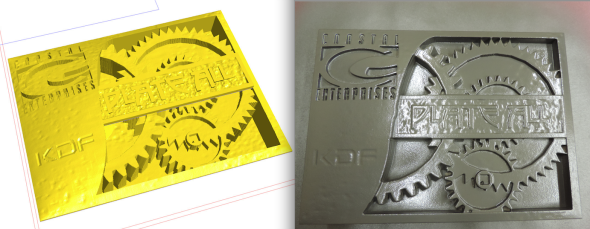

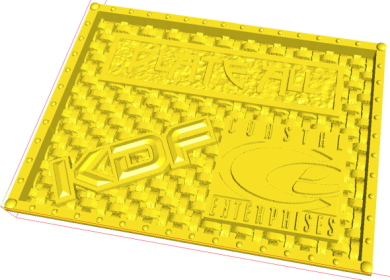

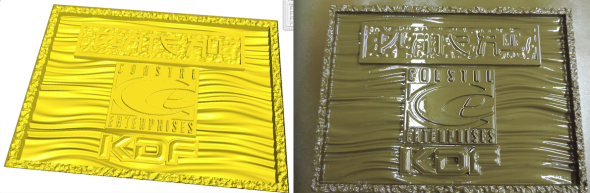

To show off this beautiful finish, we sent three samples of Precision Board Plus PBLT-30 to KDF Reprographics in Rockleigh, NJ, who created three high-detail designs using Enroute CNC software, and cut them on their CNC router.

After the pieces were routed, KDF sent them to Plate-All in Baltimore, MD, where they applied three different cold spray metal finishes – Iron, Copper and Bronze, to the three separate pieces.

“We started out by prepping the Precision Board like any other porous substrate*,” says Justin Powell, General Manager at Plate-All, “The first step was priming the board with an automotive primer to create an ultra smooth surface. Next, each piece was sanded lightly with 80 grit, working up to 120 grit to produce a rough surface and create ‘teeth’ for the Plate-All to adhere to.”

After surface preparation, it was time to apply the cold spray metal. According to John Edwards, Plate-All CEO, “Plate-All can be applied by spraying, brushing or rolling it on. We chose to spray each piece because they were highly-detailed but had little to no texture, which meant spraying would provide a unison finish and achieve a solid metal look. Brushing would be optimal if texture was desired. We endorse HVLP gravity fed spray-guns as the best option for spraying Plate-All. A siphon-fed gun may also be used, but will increase product waste and is not as efficient.”

Prior to spray application:

Spraying on the copper coating:

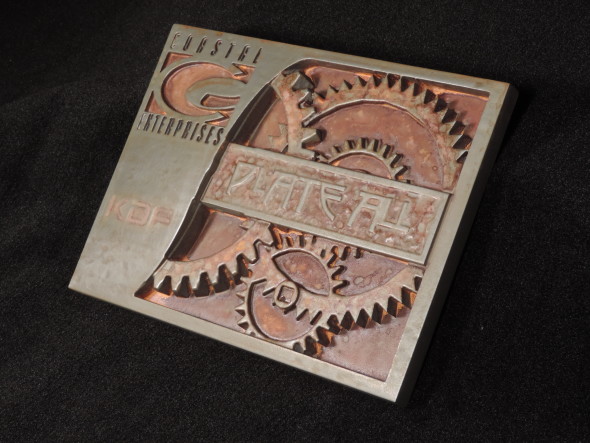

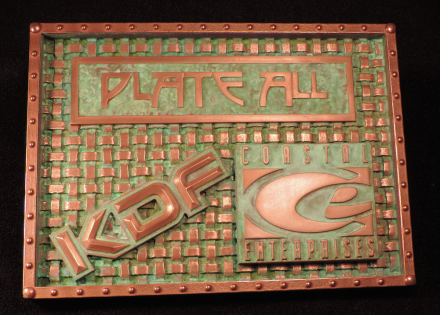

The final step is the finishing stage, which really brings out the metal-look in the finish. “Whether its a matte, satin, brushed or polished look, the final steel wool sanding stage is where it all comes together. You can also get really creative and add a chemical patina to give the piece an antique weathered look,” explains Edwards.

Bringing out the metal finish:

As you can see from the pictures, the results of each finish are beautiful. “We couldn’t have asked for a better substrate to work with than Precision Board Plus,” recalls Edwards. “The surface of the PBLT-30 is so smooth, and KDF Reprographics did such a great job with the design and CNC routing that this project was a pleasure to participate in.”

Plate-All is used in applications from interior architectural elements to harsh marine environments, and is also growing in popularity in the sign industry. The ability to provide an attractive, metal appearance, coupled with its protective qualities make Plate-All a pioneer in surfacing technology for the sign industry. Plate-All manufactures 19 different spray metal coats in total, be sure to check them all out on their website at: www.plateall.com.

One of the largest advantages of Plate-All is how easy it is to master. Request a complete training manual and DVD, or give the creative minds at Plate-All a call at: (866) 927-7701 and find out more information! ***Please note: Interested parties who mention this article will receive 15% off Plate-All training materials! Please reference code: CosKDFpla – expiration on July 1st, 2014!

“It not only looks like metal, it IS real metal!”

We will have the Copper Patina Sign on display at ISA Orlando from April 24-26 in booth #1347. Stop by our booth and admire how beautiful this sign looks in person! Click here for your free pass.

*Precision Board Plus is not porous, and moisture cannot be absorbed into it, but the top layer of cells is “opened” when it’s cut into sheets/blocks on a saw, creating the illusion that it is a porous product.

Plate-All bronze patina coating:

Plate-All iron rust patina coating: