The following Precision Board guest blog is from Hans Wendel, a teacher, and Tomasz Jan Groza, a student, both with the UCLA Architecture and Urban Design program (A.UD). They describe a recent architectural project using PBLT-20 Precision Board urethane foam to create scale models.

Here’s a more specific description of the project from the A.UD Instagram account:

“The stacked section—mute, repetitive, indeterminate—has been the foil against which many architectural projects have positioned themselves. As the primary object of study, the M.Arch. first-year studio, Section and Elevation, is concerned with the capacity of the section to move beyond seriality to develop complex spatial propositions. In an effort to challenge and interrogate the limitations of the stack the studio proposes to nest together a parking garage and a gym.”

From Hans Wendel:

In the course of the studio project students produced 1’=1/8″ scale models. One of these models, work of Tomasz Jan Groza, was realized mainly with 20pcf 1.5″ HDU foam. The model proposes a stacked system of jogged vaults to house the entwined gym and parking programs within gently undulating interior spaces.

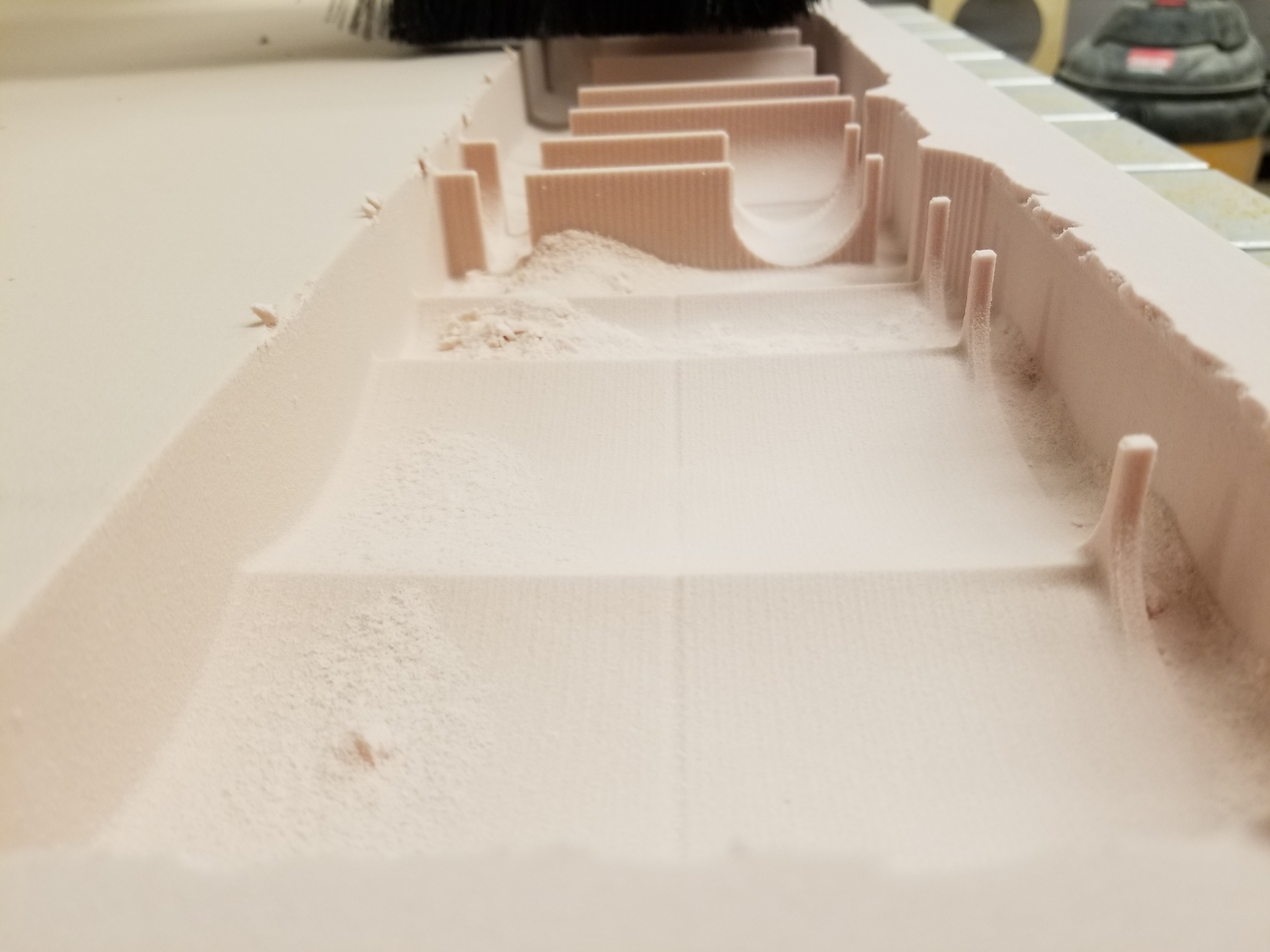

CNC Cutting in progress. Milling precision foam is quick and precise. With a 3/16” ball nose bit and moderate feed rate, even the most delicate 3D features can be carved in one pass.

Although it was possible to carve small delicate details in precision foam, handling can easily damage them. To reinforce the model 1 / 8” MDF inserts were used to make up the forest of arcaded arches holding up the vaults. They were tension fitted and spot-superglued.

Stacked assembly up-side-down and right-side-up. Partial fragments of the model in various stages can be seen in the background.

Pieces in various stages of finishing. Bulk of the model was milled out of 1.5” thick foam sheets and stacked, but some of the most delicate vertical features required a different method. Offcuts from the CNC’s sheets were used to produce foam strips about 1 / 8” thick which could be cut by hand and laser.

At this thickness 20pcf foam can bed around a two inch radius, and can be laser-cut with settings similar to 1/16” museum board. Thinning the strips with sandpaper allows the foam to bend around even tighter corners.

This fragment of the model is the ramping system for the vertical vehicular circulation in the building, It is made up of pieces of foam that were both 2D cut and 3D cut and glued together and to a wooden backer.

Finished model of the building with a sectional fragment placed on a pedestal integrated into the model base.

Section views of the model

Views of the fragment showing mainly the facade

Close up of internal section view

The UCLA School of the Arts and Architecture (UCLA Arts) is dedicated to training exceptional artists, performers, architects and scholars who are enriched by a global view of the arts and prepared to serve as cultural leaders of the 21st century. Graduate degree programs are offered in the Departments of Architecture and Urban Design, Art, Design | Media Arts, Ethnomusicology, Music, and World Arts and Cultures. The School’s unique curriculum interweaves work in performance, studio and research studies, providing students with a solid creative, artistic and intellectual foundation. World-class faculty provides a depth of expertise and achievement that supports the most ambitious vision a student can bring to the campus.

Coastal Enterprises manufactures Precision Board, a versatile, cost-effective and eco-friendly urethane material used extensively in the tooling industry. It is a closed-cell, rigid, dimensionally-stable substrate that is ideal for use in a number of different tooling applications.

Request free samples, get a quote or sign up for weekly e-blasts packed with helpful information.