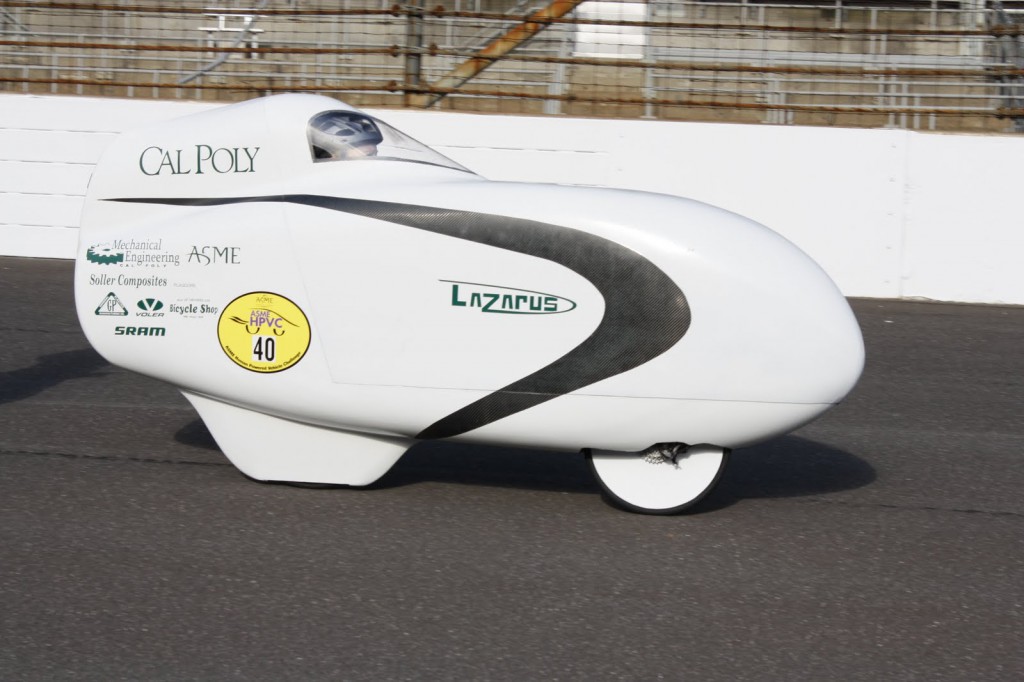

George Leone, Student Project Facilitator at Cal Poly San Luis Obispo, CA, recently sent us pictures of a project that students from the Human Powered Vehicle Club designed for the ASME Human Powered Vehicle Challenge. The human powered vehicles have been known to reach speeds of approximately 55 mph.

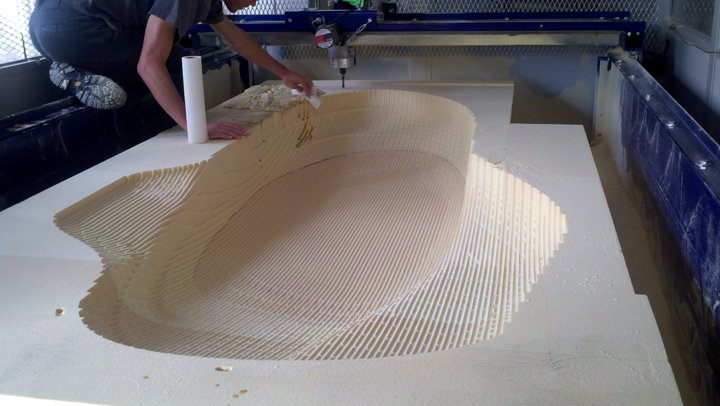

After testing the sheet-metal prototype, a mold was cut from Precision Board Plus PBLT-6 using their “hot-rodded” ShopBot CNC router. They then vacuum-bagged the molds for the bodies using a room-temp cure system. The molds were coated with Duratec for an ultra-smooth surface. Once finished, the Carbon/Kevlar bodies were fitted over a composite or Chrome-Moly frame.

The bikes are 100% built by students unless the technology is WAY beyond the capabilities or ingenuity at Cal Poly. This is also an all-volunteer club, and students do not earn credits for participation.

George has been working with composites for over thirty years. He enjoys working with Precision Board Plus because “it allows students to take their vision and turn it into reality quickly and easily, whether they are using Surform files and sandpaper or a CNC router. It’s low-dust, green chemistry composition coupled with its favorable carbon balance and renewable resource content appeal to the stewardship concerns of our 21st century engineers in training.”

Check out the pictures here:

Precision Board Plus PBLT-6 mold being routed:

Spraying Duratec for an ultra-smooth surface:

Room temperature cure vacuum bagging:

Putting together the carbon fairing:

The bikes:

Lazarus:

Atlas: