At Coastal Enterprises, we like to look at the composites industry as a fully collaborative effort. Every fresh new development by an individual is really a contribution to a collective knowledge base. Like any scientific pursuit, the most potent advancements are made when information is shared freely between likeminded groups of people. For this reason, we feel obliged to do everything we can to enlighten and empower the future community of composites professionals. In our experience, this new generation can often be found in university engineering programs, like the Cal Poly SLO Human Powered Vehicle team. Coastal has supplied the team with Precision Board for many years now, and every year they’ve shown up to the ASME Human Powered Vehicle Challenge with a design that really showcases the capabilities of our material.

The driving force behind the team is George Leone, student shops manager and technician, a man with over four decades in the composites industry in one form or another. George has been building composite streamliner HPVs since the 80s and is one of the foremost authorities on the design and construction of human powered vehicles. His philosophy for guiding the student team members is to provide them with the necessary tools and instruction, then turn them loose to create an individual project that stems from their own ideas and hard work. By maintaining a positive, constructive environment where students can learn by doing, he ensures that senior students can eventually step into leadership roles and help guide their younger teammates.

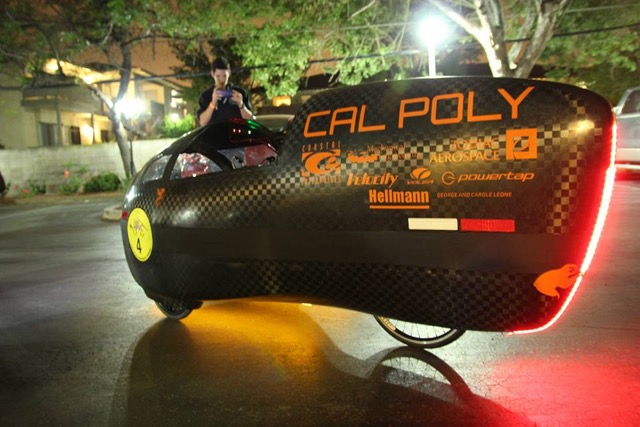

For last year’s entry into the HPV competition, the team created a carbon-fiber/Kevlar composite streamliner they dubbed the “Sweet Phoenix”. Coincidentally, when George Leone built one of his first streamliners back in 1980, he named it “Phoenix”. Risen from the ashes indeed. The Cal Poly team started by enlisting the help of Zodiac Aerospace to create the molds, thanks to the inopportune breakdown of their aging Shopbot CNC router. The team used PBLT-8 and machined out two halves of a negative mold, meaning that the carbon composite material would be pulled down into the recess to create the sleek teardrop-shaped body.

Students prepped the molds by sanding thoroughly before applying Duratec sealer and primer. The quality of the PBLT-8 was paramount to the end result. As George put it: “The consistency of the foam and it’s impressive ability to hold a sharp edge, even with inexperienced handling, made us glad we chose Precision Board.”

At the 2015 ASME Human Powered Vehicle Challenge West, the Sweet Phoenix performed admirably, despite a puzzling last-second drive train glitch. Complications aside, the SLO team took home first prizes in both the Design and Men’s Speed categories, a crowning achievement for such a prestigious event. The 2016 team plans to use the same leftover molds, thanks to the durability of the Precision Board. Even after being stored outside for nine months, the molds only required some light sanding and priming to restore them to pristine condition.

George Leone and the Cal Poly HPV team are prime examples of the spirit of invention and collaboration that are deeply engrained in the composites community. All of us at Coastal wish them luck and speed in this year’s competition! Click here for a free sample of Precision Board and spearhead your next composites project!