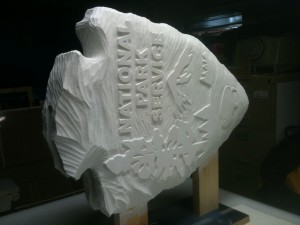

1. Carbide cutters are not mandatory when working with Precision Board since it is non-abrasive. Precision Board can be cut with standard HSS cutting tools.

2. To maximize CNC efficiency and cutting time, and to minimize dust and increase chips, the Onsrud Router Bit Selector Guide provides guidelines for proper router bits, speeds and feeds.

3. After you have primed Precision Board Plus using FSC-88WB Primer/Filler, it is best to dry using a large shop fan. Do not place in the sun, as this will cause it to dry too fast (skin over) resulting in blisters. The FSC-88WB Primer/Filler training video can be seen here.

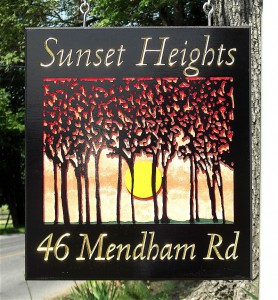

4. Be sure to prime and paint all sides of your HDU sign because of paint tension balance. Because it does not have grain, it has no beam strength and can be pulled in the direction of the drying paint.

5. When sandblasting Precision Board, set your PSI to about 60, at the pot. To achieve a larger texture, use higher grit. Similarly, a finer grit allows for finer texture. Aluminum oxide is used most often.

6. If something happens to your sign during the build process, it is possible to fix the damaged surface. FSC-360WB Crack Filling & Repair Putty dries quickly and sands easily, and can really save the day in the event of a mistake.

7. Optimize your leftover Precision Board by bonding and laminating the extra pieces. Use PB Fast Set or PB Bond-240 adhesive.

8. PB Resin is a 2 part epoxy that paint can be added to. Use on flat surfaces to achieve smooth, glossy surface. No priming, sanding, or painting needed. Call for free samples of PB Resin or any of our companion products.

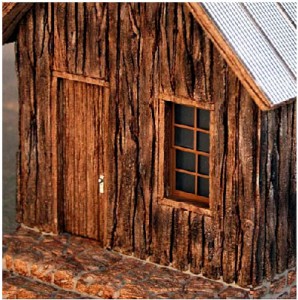

9. If you do not have time to rout, or sandblast a wood grain texture, TSF-45 or PB Hardcoat are excellent time saving alternatives for simulating wood grain. Apply both directly to raw Precision Board, eliminating the priming step.

10. If you have a question, call us at 800-845-0745! We offer free technical support and are happy to assist in any way we can. You can also request a sample of Precision Board HDU or get a quote.