National Composites Week is designed to introduce young people and others in the community to the composites industry, the career opportunities available, and demonstrate the contributions composites make to the local, national and global economy. Coastal Enterprises manufactures Precision Board, a high-density urethane tooling board used extensively in composites, including industries like aerospace, automotive and marine and in a variety of applications including molds and prototypes.

We’ll be sharing various ways that Coastal supports composites throughout the week.

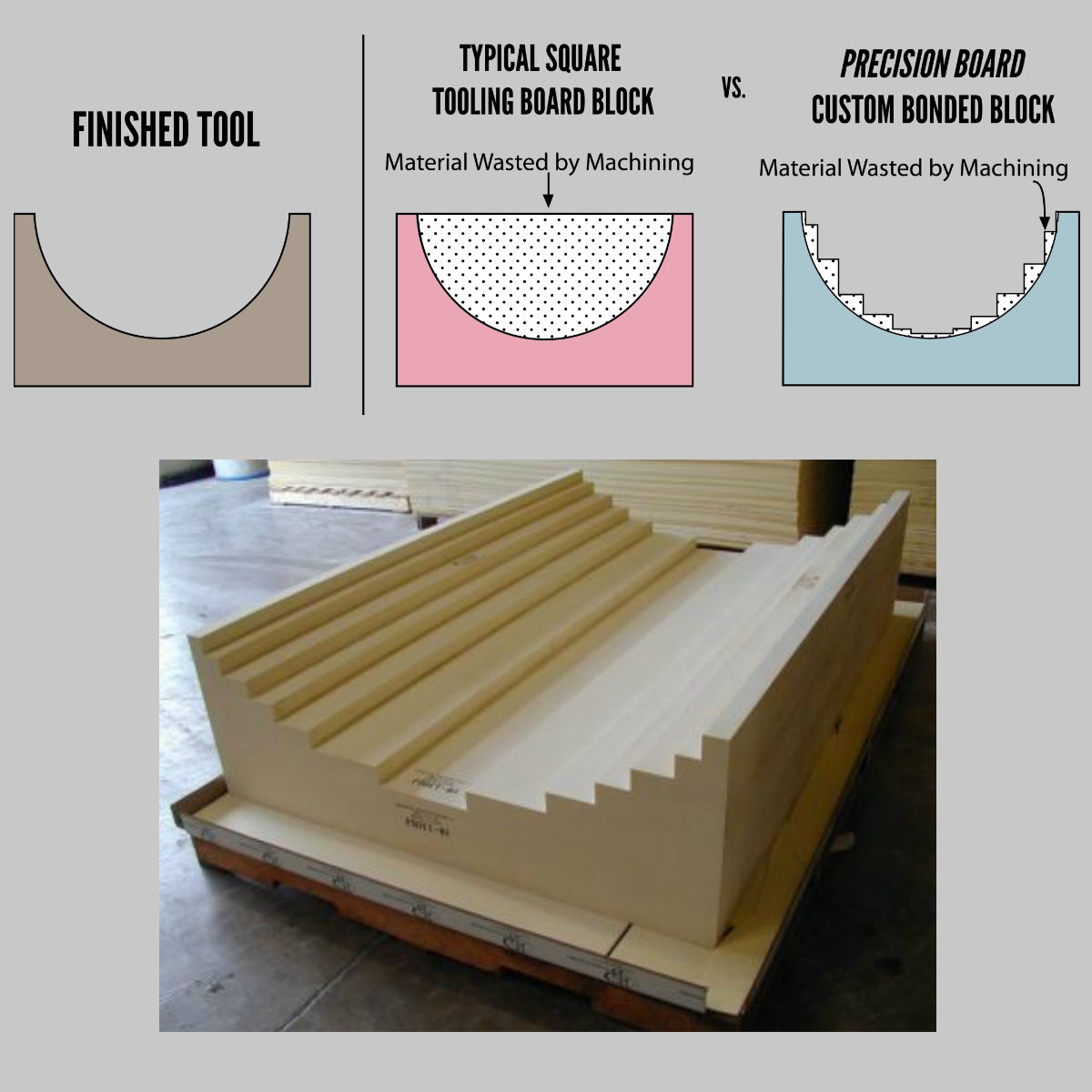

Today’s Topic: The creation and benefits of Precision Board step-tools

The aerospace and automotive industries have relied on Coastal Enterprises for years to provide custom-bonded Precision Board urethane tooling blocks for their unique composite layup tooling needs. From small and simple to large and complex, we offer fast turn around and competitive pricing on custom tooling board blocks. We can take the guesswork out of building your composite lay up tool. Working from a CAD drawing of your tool, we design and fabricate a custom block using Precision Board that is ready for machining. Virtually any shape, size or level of complexity, our bonding expertise will help you keep your project on schedule and on budget.

We have the capability to bond very large or very small blocks depending on the application. We can also fabricate anything from complex geometric shapes to basic shapes, based on specs provided by the client in the form of drawings or even a simple sketch.

Step-tools bonded in-house by Coastal have nearly imperceptible bond-lines with less chance of bond-line failure, less chance of bond-line shrinkage and / or print.

Our large inventory of fully cured HDU blocks allows us to get your custom bonding project out the door fast! Many clients choose our custom bonding service to reduce production time. Letting us bond your HDU project allows you to focus on the machining and final shaping.

In tooling applications, we bond our blocks with EP-76, a two-part epoxy we make here at Coastal. We add our PB Granules to the epoxy to match the density of the material being bonded, resulting in seamless bond-lines. This also means the CNC operator doesn’t need to take harder bond-lines into consideration when machining Precision Board.

In our experience, if your tool is larger than can fit on a desk top, we can save you money bonding it in house at Coastal Enterprises. Contact our technical sales department for help with a cost analysis to determine how much time and money you could potentially save by having us do the bonding for you.

Still have questions about our in-house custom-bonding? Call us at 800-845-0745 to talk to our experienced technical staff, request a quote on a bonding project, or send us an email with your questions.

National Composites Week Schedule

Monday- Coastal’s School Donation Program

Tuesday- What is soft tooling and how has it changed the composites industry?

Wednesday- The benefits of Precision Board over other tooling boards

Thursday- The creation and benefits of Precision Board step-tools

Friday- Coastal’s long history and roots in the space program

A group of composites industry leaders has announced the creation and launch of the inaugural National Composites Week, Aug. 26-30, 2019. The goal of National Composites Week is to encourage manufacturers from throughout the composites manufacturing supply chain — raw material suppliers, convertors, designers, toolmakers, fabricators, educators, students — to celebrate and bring attention to the myriad ways that composite materials and composites manufacturing contribute to the products and structures that shape the American manufacturing landscape today. More information is available HERE.

National Composites Week was organized and launched by braiding specialist A&P Technology, global advanced composites company Hexcel and media partner CompositesWorld magazine.

Coastal Enterprises manufactures Precision Board, a versatile, cost-effective and eco-friendly urethane material used extensively in the tooling industry. It is a closed-cell, rigid, dimensionally-stable substrate that is ideal for use in a number of different tooling applications.

Request free samples, get a quote or sign up for weekly e-blasts packed with helpful information.