Blogs

Hells Gate revisited

Almost ten years ago we built a new proscenium for the Hells Gate Airtram attraction. The airtram is situated in a spectacular river canyon and features a 500 foot drop from the highway to the far side of the river. The canyon narrows to just over a hundred feet wide at that point and is well over a hundred feet deep. More than twice as much water flows through this narrow canyon than over Niagara Falls.

At The Movies.

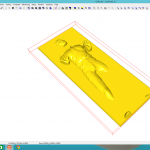

A while back, I remembered seeing a Han Solo in carbonite sculpture that caught my eye. It was made by a well known sign shop on the east coast and all I could think to myself was ” I could do that!”. Well, months went by, and I still never had the time to mess around with it.

Cultus Lake Adventure Park finished!

The Cultus Lake Adventure Park project is now wrapped up and operational. After so many months of work on the project it is great to see the park in operation. The signs look great in their intended setting! The rides in this section of the park are much more extreme and the theme work is a little more sparse.

Denver Workshop coming fast!

We are now putting together the agenda for the three day Denver Workshop in mid-September where I will be presenting along with Jeff Harman and Thad Staples. We’ll be covering everything from basics through fully dimensional pieces. There will also be plenty of hands-on in the evenings including how we finish our pieces. It promises to be a great workshop.

Why not in the real world too!

In the last four days I’ve grabbed more than twelve hundred photographs of everything Disney. What I’ve seen is nothing short of breath taking. Such wonderful attention to detail and story telling at every turn.

Free yourself from the insanity of Zebra analysis with Autodesk Shape

So you’re working on your surface model, and you are trying to get everything to match up nicely, usually to either G1 (tangent) continuity, or G2 (curvature) continuity. You think things look pretty good, you join them all together, you run ShowEdges to see if your model has any naked edges……and then you use Zebra to check that your edges are continuous in the way you desire. Which, frankly, I think is completely nuts. Allow me to explain.

Trip for inspiration

This week Peter and I are in Tokyo visiting the two Disney parks here. The Disney Imagineers are the very best in this industry and these two parks demonstrate that at every turn. This week we will observe and record as much of that creative work as possible. In two days I’ve taken more than 900 photos. Wonderful design abounds with great examples of CNC routing.

Why we build our surface models from scratch

Well, it’s time to dust off this blog and get it going again! It’s been way too long. Let’s just say life happens sometimes, but I’m glad to be back at this again. So, to kick off the first post, I’m going to talk about something that we spend a lot of time talking to customers about when we build surfaces from laser scanned data. We’re often asked, “Why do you use Rhino3D to do reverse engineering work, instead of one of the purpose made reverse engineering software platforms?” The short answer comes down to one word – quality.

Paint paint paint

The last few weeks have been largely all about paint as we near the end of the second phase of the Cultus Lake Adventure Park. For that project there were three main signs. I’ve posted the various phases of the project in the last weeks. Here’s a series of pictures showing the painting of these projects by our talented crew.