Blogs

instant install

The new MultiCam tech centre and office in Langley, British Columbia opens on Friday. That meant it was time to do a special delivery today. Grant and I loaded their new sign nd a few tools into the back of the shop truck and we headed down the road. Kelsey was at the office eagerly waiting for us to arrive

Full throttle story telling

A simple electrical on-off switch would have done the job of turning my MARVELOUS MACHINE on and off. But a simple switch wouldn’t have told the story I needed to tell. My MARVELOUS MACHINE is ‘driven’ by steam. To properly control suck a divide we needed a mechanical throttle, much like what one would find in an old steam train engine. I had built a similar throttle for our train steam engine last year

Last of the arches sculpted

The NEBs bowling alley project temporarily took a backseat to some other pressing projects but as they went out the door we went back to work on the last of the arches for the bowling alley. Today we reached a milestone as the last two of the concrete arches were hand sculpted today. There were twenty-six arches over the bowling alleys and another five arches down each side of the massive room, making thirty-six arches in all. We have five more beams to complete as well as twelve posts for the centre of the room.

AXYZ Open House This Week in Anaheim, CA

Coastal Enterprises in Orange, CA, was a must-stop location for Noel Archie with AXYZ International, Burlington, ON, Canada, when he came to town for their Open House. He needed some last minute training on PB Resin for his sign he's making with Precision Board for...

Meet Rob Estes, Hand-Carving Signs with Style from Paducah, KY!

Rob Estes, of Brushstroke Signs in Paducah KY, wants everyone to know that hand-carving is still alive! Rob has been making signs since 1985 and has always been an avid hand carver and hand painter. He’s been using Precision Board Plus for years for his dimensional...

Renovations Part 1.

A few months ago, I walked in the shop and stopped in the entryway. I looked around and thought, this is nice, but it’s not really Synergy. After some careful brainstorming, the hammers came out, the paint brushes began to fly, and the Multicam CNC Router began cutting parts. The first step was to texture all of the walls with Coastal Enterprises TSF 45 texture coating. We used 3 gallons putting a nice heavy texture on the walls.

New Challenger: Phase Two: Turning 2D to 3D, It’s harder then it sounds

I have a concept, I figured out my scale, now to start actually building… ugh… Where to begin? Jim and I sat down with my concept sketch and started figuring out materials we should use. This can somewhat be overwhelming, but we approached it by dividing the piece in half. We started with the base, The bottom pretty much needs to be the strongest and most durable

New Challenger: Phase One: Use all the math you learned in school, that you never thought you’d actually ever use.

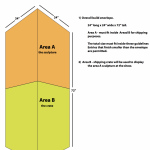

Phase One: Use all the math you learned in school, that you never thought you’d actually ever use. I have a concept! Now what do I do? Well… I guess I can put the engineering degree to use and start drawing my piece to scale. I started with the basic dimensions a 24in x 24in base, as stated in the contest rules with a total height of 72 inches. Easy enough, right

New Challenger

A few months ago the invites for The Sign Invitational went out, I thought nothing more about it really besides the theme and some ideas came in mind for the shops entry. As some of you may know, Jim and the shop helped organize a contest last year, where a bunch of sign makers challenged each other to create a dimensional display piece. Synergy pla ced 3rd and that was the first month I started at the shop and my first big project.