Blogs

Four pound delight

I’ve been a vocal advocate for thirty pound foam for a long time. For CNC routing that isn’t about to change. But occasionally we build small study models which require lots of hand work. Thirty pound Precision Board, our material of usual choice, is tough to work by hand – especially at this scale.

Machining tips and more!

-A message from Chuck Miller, CEO of Coastal Enterprises “Over the years Coastal Enterprises has continually worked to improve Precision Board to meet the changing market needs and requirements. In the last few years change has come even faster to designs and tooling...

Imagine the possibilities

When we installed our MultiCam CNC plasma cutter last week we weren’t sure exactly what we would do with it. We just knew the things that are now possible in our shop will be very cool and unlimited in scope. It was the same with the MultiCam CNC router ten years ago. Today Peter designed the brackets for the gutters they will install on their house. The image was drawn by hand and then imported into EnRoute for vector tracing which only took a second

Dino comes to life

The dinosaur bones were slipped over a bent steel pipe to form the backbone of the velociraptor. I spaced then out and took a look to see how it would work. It needed a little tweaking and twisting to get things looking right. To give the skeleton more life I cut both ends of the pipe and added more bend before welding them back on at a slightly different angle.

Never stop learning. Again.

I consider myself somewhat of a power user when it comes to using our cnc machining software, Enroute Pro 5.1. So why in the heck and I spending 3 days training on the software in Denver, Colorado?. Simple.

Edge Bonding: A PB-Fast Set walk-through

Out technical staff at Coastal Enterprises has received questions frequently in regards to using PB-Fast Set for edge bonding. Here is a quick step by step picture aided explanation of how it’s done. This sample of PBLT-15 was cut into two pieces. Our goal is to use...

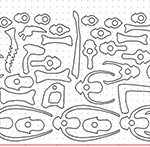

Pile of bones!

Once we got the new MultiCam plasma cutter set up and tested it was time to give it a spin. Russell asked me for a file and I was happy to oblige. It was time for Phoebe’s mailbox to be cut at last! It was pure magic to watch it run through the file! It ran flawlessly – right out of the box! We had quite the pile of pieces when the machine was done.

The Artists Who Happen to Make Signs – The Angry Bull

I’m sure you’re familiar with the phrase “taking the bull by the horns.” Well Xpressive Graphix takes the phrase to a whole new level. Creating a sign for the Angry Bull Saloon is a prime example of what the artists at Xpressive Graphix are capable of while following...

Digging up some old bones

Yesterday, Russel Boudria, the head trainer from MultiCam in Texas arrived to set up our shiny new CNC plasma cutter and train us how to use it. He was eager to get started even though he had spent most of the day in transit. That’s dedication! We worked a couple of hours levelling the table, sorting out wires, hoses and cables, and testing things out. We got to the point where we could move the gantry and test fire the machine. Tomorrow we’ll begin some serious cutting