Blogs

Sign Challenge progress

Peter has now finished the sculpting on his Sign Challenge piece and has moved on to the painting process. It is looking pretty amazing!By the end of day tomorrow he should be into the glazing and aging process. My piece has most of the base colours finished but we still have to do a little sculpting on one small element. Once that is painted we will move on to the aging and glazes

CompositesWorld: Carbon Fiber 2015

Landmark composites convention kicks off in Knoxville, Tennessee The composites industry is constantly looking towards the future, providing the means and materials for the next groundbreaking technological advancement. Every manufacturer is racing to discover the...

Trade show booth – part three

The current large project underway in our shop has used our MultiCam plasma cutter in a large way. It has in fact caused me to fall in love with the handy, dandy machine and the ease in which we can create custom metal parts. We’ve taken the design/build approach. Each piece is first sized up visually.

Trade show booth – part two

I drew up concept plans for an entire West Coast town more than five years ago. Every building and structure was styled in an energetic, steampunk/nautical flavour. I had a lot of fun creating the concepts but unfortunately the group was not able to get the funding necessary to proceed and the plan died. Those concepts (which I still own) have lain dormant in my files ever since.

Train model done

Today Jenessa glued on the last small bits and and painted on the last brush strokes to finish both train models. They look spectacular! As soon as we get the final measurements from the train chassis builder we will start in on the full size version.

Arms and legs

Each time I get a few minutes I add more pieces to the Sign Challenge piece. It is largely hand sculpting at this point. The latest additions are the rocket legs and the rocket engine. The piece is a parody of the sign making industry and makes commentary on two long standing issues. The first is the old time ‘snapper’.

Starting the sculpt of the vehicles

Once the accurately routed vehicle forms are securely anchored in place, it is relatively easy and quick to apply thin coat of sculpting epoxy and sculpt in the fine details. The character armatures are first built from twisted wire, over which I press on a little sculpting epoxy to form the basic shape. Once cured a final layer is again pressed on and the details are sculpted in. The motor cycle was first along with the form for the girl hanging on the back

The Sign Invitational

A while back, a brainstorming session involving Dan & Peter Sawatzky, Jeff Hartman, and Myself, yielded one of the better ideas I have heard in a long time. The Sign Invitational was born. The contest is simple. Set up some build rules that govern theme and size, then invite 20 amazing sign makers to participate in the challenge. The registration deadline passed on October 31st and I’m proud to say we have 14 amazing sign makers competing.

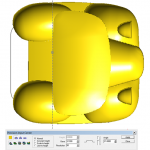

Building the vehicles – part four

When we left off the vehicle was looking pretty good but now it was time to start in on the customization to make four different vehicles. The vehicles would be a pickup, a long flatbed truck and a short flatbed cab over. Behind the bar were three round corner rectangles. I selected them and made them into a 1″ tall relief.