Blogs

Sign Shop Sign

Our good friend Robin from Foley Sign Shop in Orangeburg, NY was in the market for an oversized dimensional sign at her great new location. We were happy to work with her on it and had a little fun with her great logo. The bed on our Multicam 3000 is 4’x8′ – the sign will be 5’x8′ so we are going to have to piece it together. We are cutting the Palette out of 2″ 15# Precision Board HDU and the letters out of 1.5″ 30# Precision Board HDU. To lighten the sign we hog out some material. Once We’ve assembled the palette we cut the letters and other elements.

Scribbling ideas

When I received my invitation to the 2016 Sign Invitational it didn’t take very long for me to think up a great idea. Not long at all. I quickly grabbed my sketchbook and over the next hour filled ten or twelve pages with scribbles (to most) of ideas.

2016 Sign Invitational

I absolutely love a challenge and when this arrived in my inbox I jumped at the chance! Of the twenty invited sign makers there have been twelve of the world’s best respond already. The competition is going to be incredibly intense and fun! Best of all of the entrants will be gathered in Orlando at the International Sign Show for everyone to talk to and perhaps garner some great tips. I look forward to seeing the entries all lined up in a row. MultiCam has stepped up as a sponsor of the display space for the entries. Precision Board (Coastal Enterprises) has also signed on as a sponsor

2016 Sign Challenge

I absolutely love a challenge and when this arrived in my inbox I jumped at the chance! Of the twenty invited sign makers there have been twelve of the world’s best respond already. The competition is going to be incredibly intense and fun! Best of all of the entrants will be gathered in Orlando at the International Sign Show for everyone to talk to and perhaps garner some great tips. I look forward to seeing the entries all lined up in a row. MultiCam has stepped up as a sponsor of the display space for the entries. Precision Board (Coastal Enterprises) has also signed on as a sponsor.

Adding a little color

Two of the models are now in the paint stage and coming along nicely. It won’t be long until they are finished. The little tugboat is sporting all of it’s base colors and is ready for the first of it’s glazes.

Drilling for an Eye-bolt

Drilling holes in Precision Board has many similarities to wood. However, there are some differences that should be noted. This blog will feature step one of two for hanging a sign using an eye-bolt. Here is a step-by-step picture and video guide to show you how to...

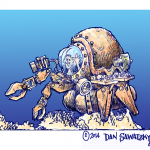

Start of the sunken ship sculpt

Angie and I made good progress on the sunken ship model today in two one hour sculpting sessions. She mixed the epoxy while I sculpted, except what I was called away and she got to do the little crab on the rock beside the ship. In an hour or two at most tomorrow we should have this thing ready for paint. Since its a study model to be used to talk to sponsors of the attraction I didn’t overly fret about detail, instead concentrating on capturing the story and mood. It’s coming together nicely and should paint up pretty nice

Texturing Made Easy: TSF-45

Creating a wood texture finish, cross-hatching for an extra dynamic dimension, or achieving the perfect stucco effect can be made easy with TSF-45. This tough yet flexible coating has been made specifically to create a variety of texture finishes on Precision Board,...

Sub model – part one

The second project study model we are building is a submarine. But it’s not a typical sub. This one is designed to appeal to kids… something they would imagine to explore the deep